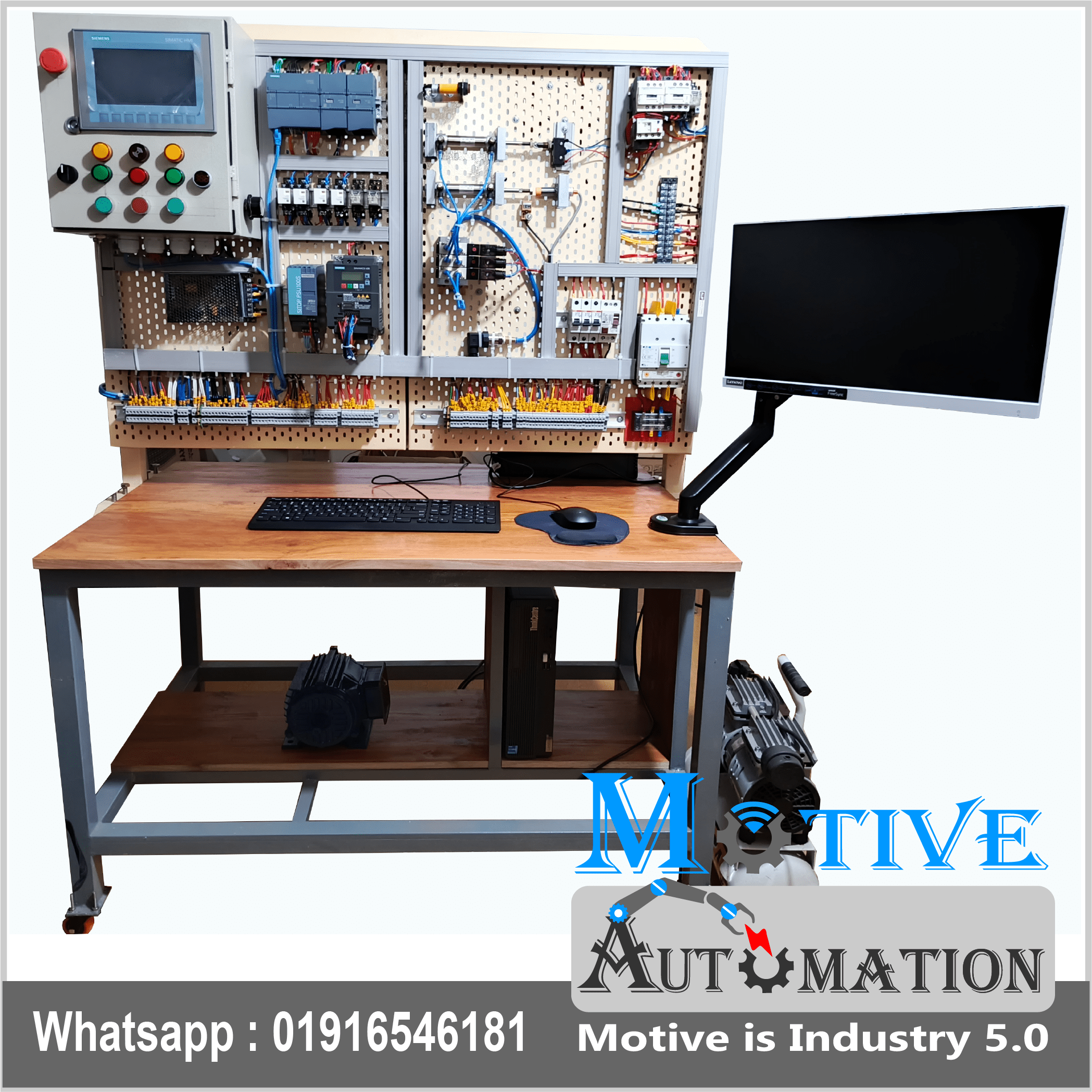

The SIEMENS Advanced PLC Trainer All-in-One Kit is a compact, modular, and industry-grade training solution designed to deliver hands-on learning in advanced automation and control systems.

Built around the powerful SIEMENS S7, series PLCs and featuring HMI integration, this kit is ideal for universities, technical institutes, and industrial training centers aiming to teach real-world PLC programming, smart factory concepts, and industrial automation.

🔧 Key Features:

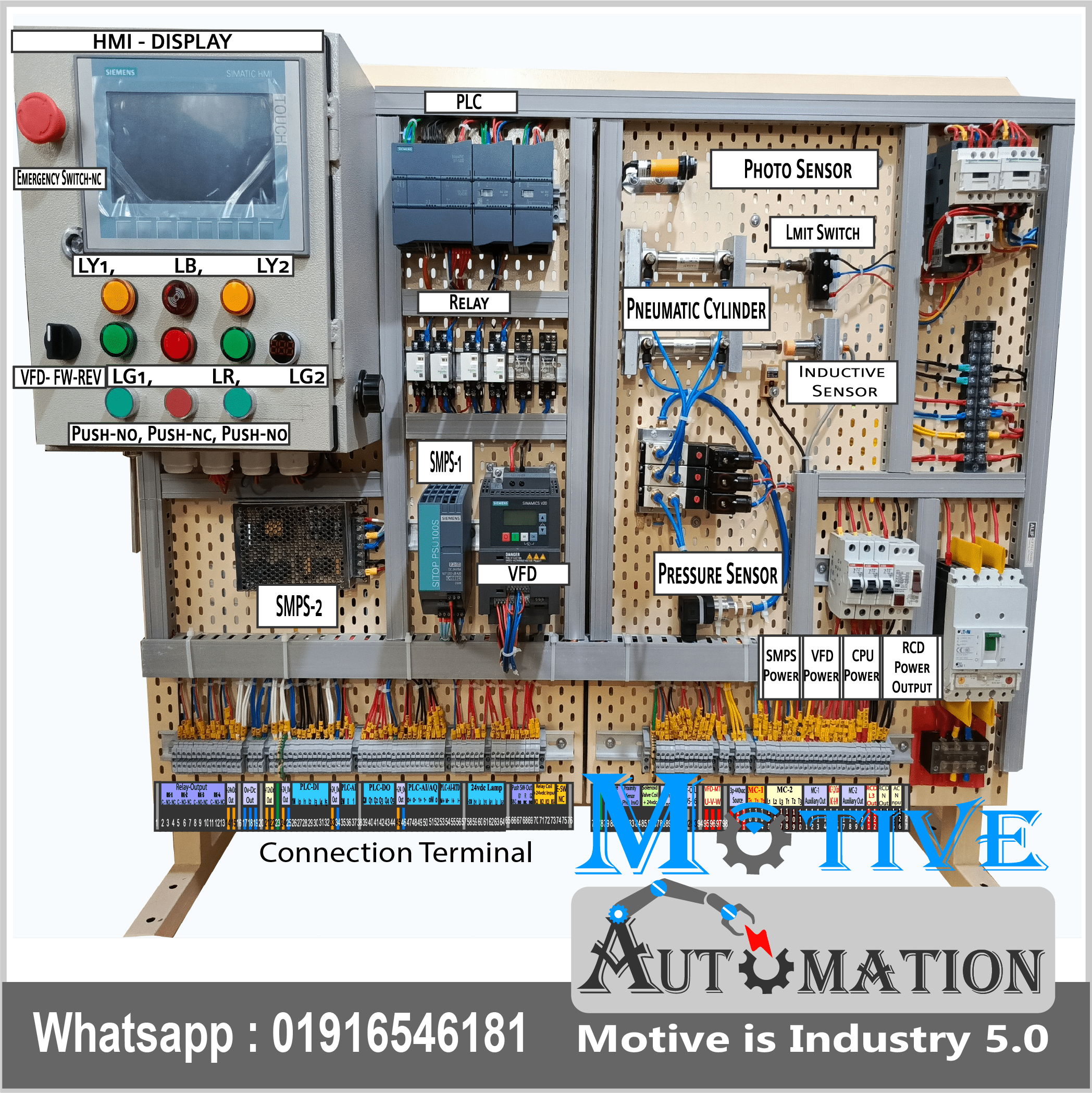

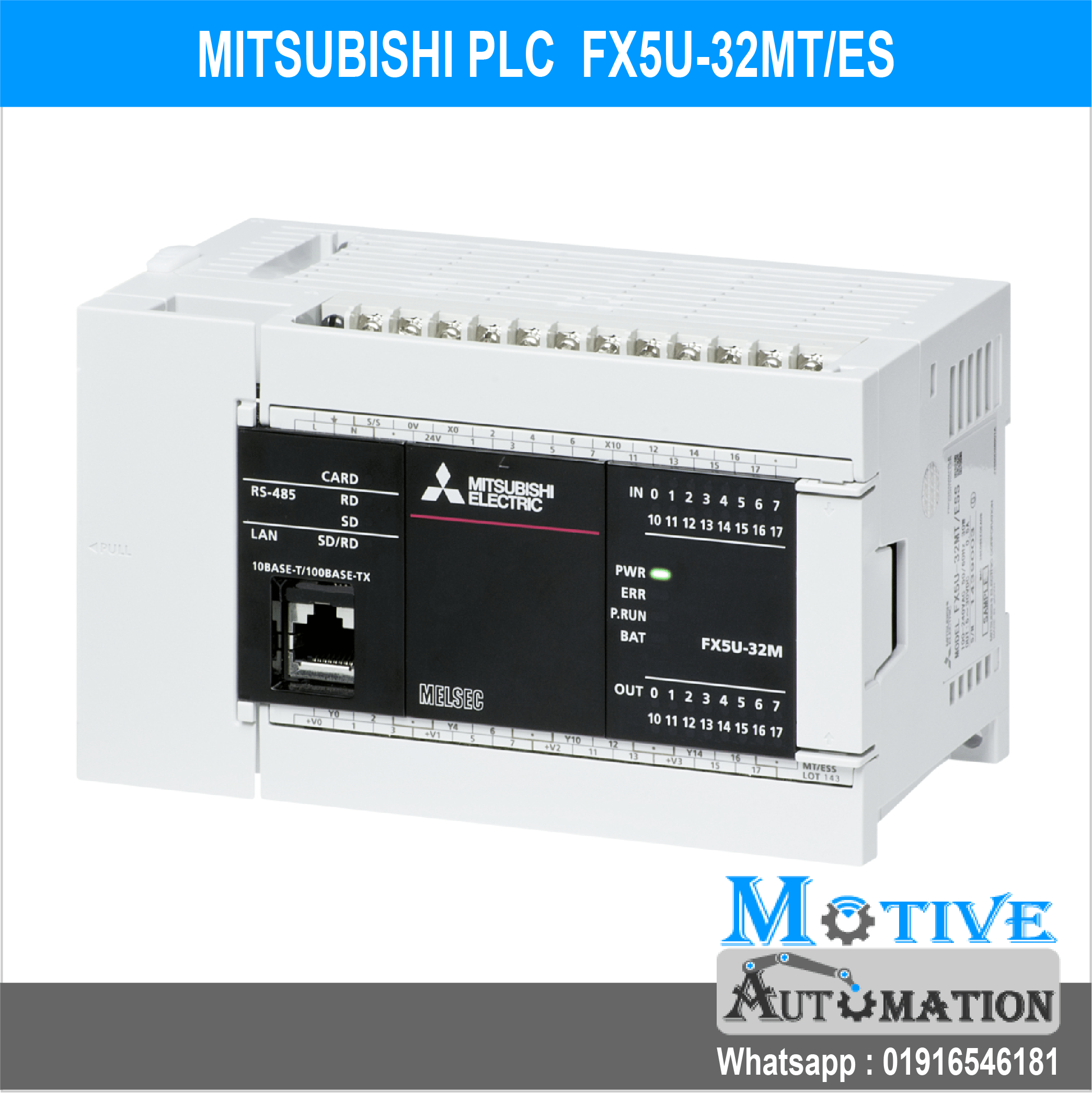

✅ SIEMENS PLC (S7-1200 / S7-1500) Learn LAD, FBD, and structured text programming using TIA Portal.

✅ Integrated HMI Touchscreen Design interactive HMI screens for real-time process control and monitoring.

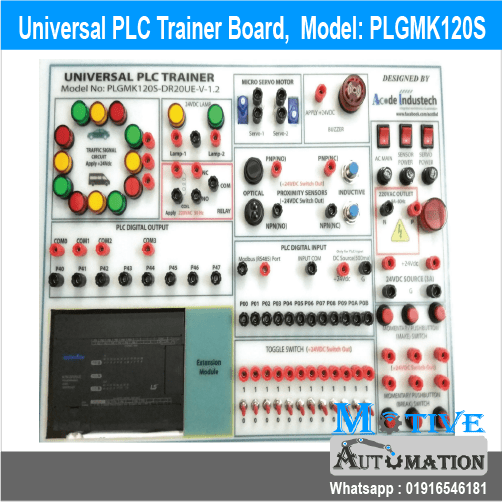

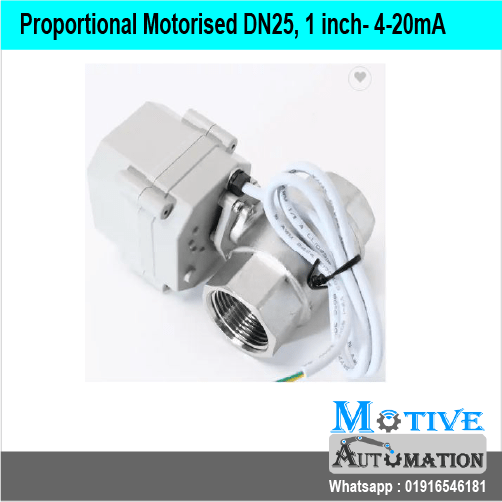

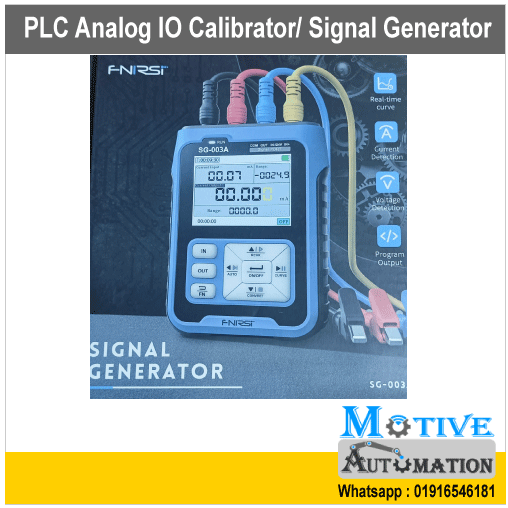

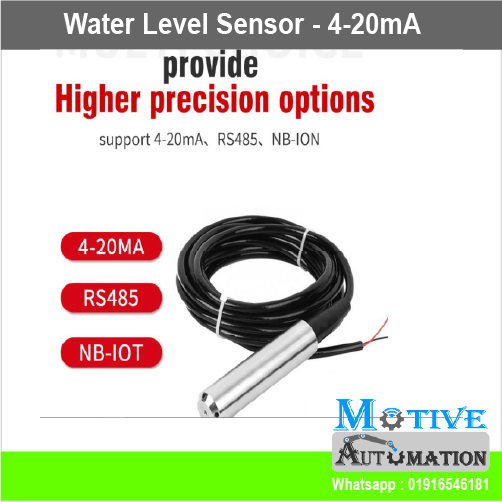

✅ Digital & Analog I/O Modules Experiment with sensors, actuators, and analog signals (0–10V / 4–20mA).

✅ VFD Control (Optional) Interface with a Variable Frequency Drive to control motor speed via analog output.

✅ PROFINET & Modbus Communication Configure industrial networks and enable seamless communication between PLCs, HMIs, SCADA systems, and third-party devices.

✅ High-Speed Counter Support Handle encoder inputs and high-speed digital pulses for precision applications.

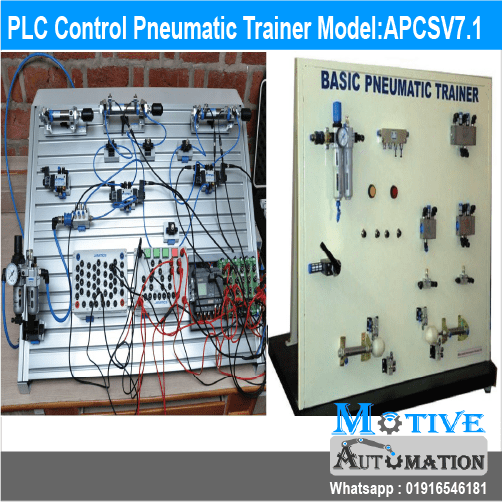

✅ Industrial Pneumatic Control System Train on real-world pneumatic components with PLC-based valve control.

✅ Pressure Monitoring & Control Use sensors to simulate pressure control applications in industrial environments.

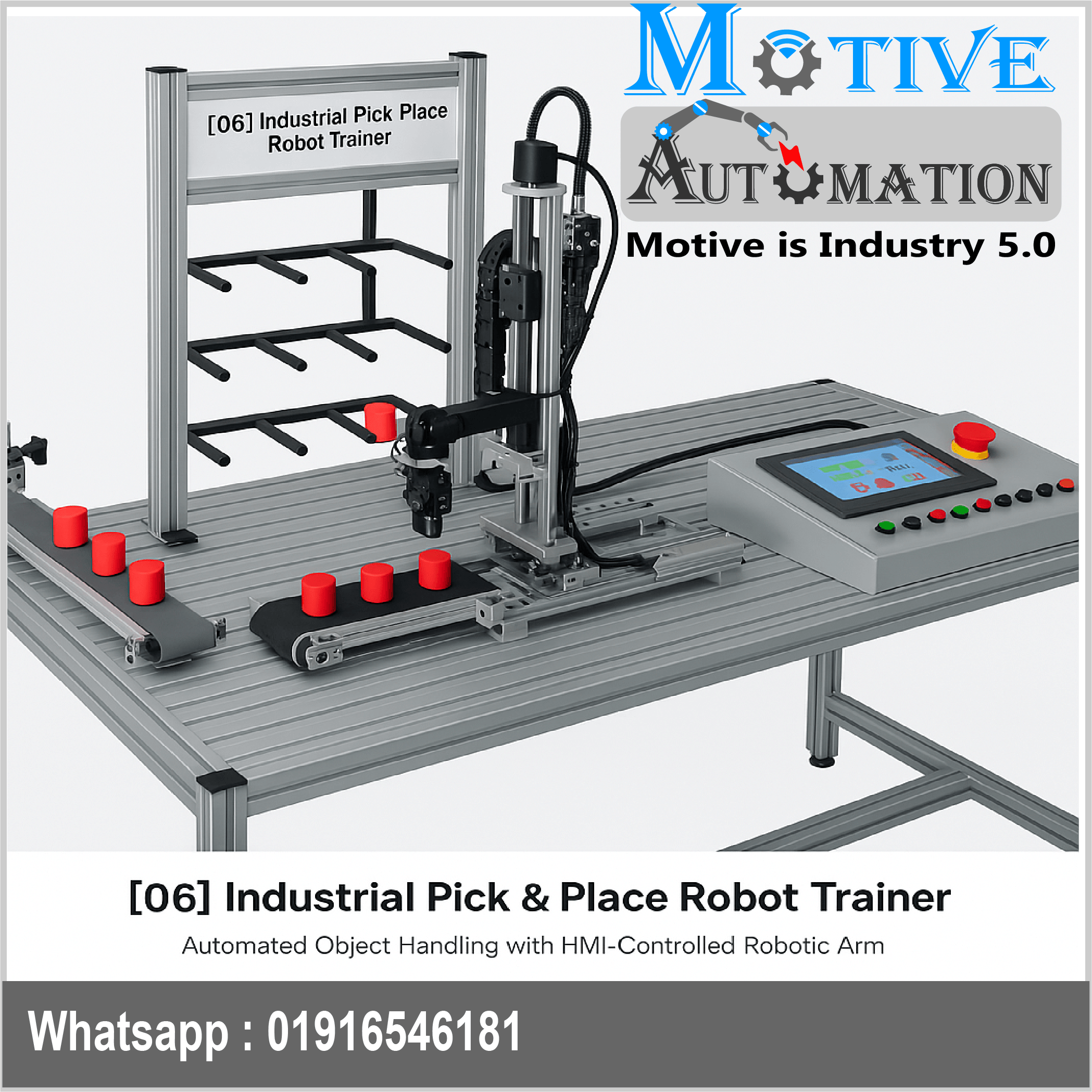

✅ Integrated Industrial Bottle Filling Project

A realistic mini-project for automating and monitoring a bottle filling process is ideal for understanding multi-sensor and actuator coordination.

✅ Onboard Sensors & Modules Includes temperature sensors, proximity sensors, inductive sensors, encoders, relays, and digital indicators.

✅ SCADA Integration (WinCC) Compatible with SIEMENS WinCC SCADA for real-time data visualization, control, and analytics.

🎓 Learning Outcomes:

- ✨

PLC Programming: LAD, FBD, STL - 🖥️

HMI Screen Design & Data Binding - 🔁

Analog Signal Processing & Feedback Control - 🧩

Sensor Interfacing & Actuator Control - 🌐

Industrial Networking: PROFINET, Modbus - ⚙️

Motor & Pneumatic System Control Logic - 🌍

Web-Based Remote Operation & Monitoring (IIoT Ready) - 📊

SCADA Visualization using WinCC Runtime

Training Features

📘 Basic Introduction-Based Training

🔌 Circuit Connection-Based Training

🎛️ VFD-Based Training

🖥️ PLC Automation-Based Training

📟 HMI-PLC Automation-Based Training

🏭 Pneumatic Control System Training

🌡️ Industrial Temperature Control & Monitoring Training

⚡ High-Speed Encoder System Training

🛠️ Maintenance and Troubleshooting Training.

⚙️ Programming Features and Projects of PLC Training Kit:

🔀 Logic Gate Operations

💡 LED Digital Control Using

⚙️ Industrial Conventional Motor Control

📈 Analog Operation (ADC, PWM)

🖥️ HMI Interfacing with PLC

🎛️ HMI Programming

🔢 Display Motor Runtime Frequency & RPM on HMI via Modbus Communication

⌨️ Graphical Keyboard for PLC Data Register Value Input

🔗 PLC-VFD-HMI PROFINET Communication

🚨 Industrial Alarm & Error Log System Using PLC-HMI

🛡️ Industrial Relay Control with

⚡ Industrial Motor Control with

🎚️ Induction Motor Speed (Frequency) Control with PLC & HMI via Analog I/O

🌡️ Temperature Controller with HMI & PLC

📐 PLC – VFD PID Operation

📡 Onboard Proximity Sensor Module (Inductive, Capacitive, Photoelectric) practical

🏭 Onboard Control of Pneumatic Cylinders from PLC – SCADA

🌀 Onboard Encoder and High-Speed Pulse Generator, Monitor PLC- SCADA

🌍 Remote Motor Control and Temperature via PLC Web Server

📊 Temperature and Humidity Monitoring Using SIEMENS WinCC RT SCADA Visualization

🛠️ Air Pressure Monitoring via PLC Web Server

🎓 Students can explore and learn from over 50 real-world industrial projects.

Materials

|

SL No. |

Specification |

Unit |

Remarks |

||||||||||||||||||||

|

1 |

|

1 |

Set |

||||||||||||||||||||

Reviews

There are no reviews yet.