- Shop

- Vendor Registration

- Vendor List

- Articles & News

- EEE and Automation Skills Training

- Training Kit- University-Polytechnic

- AC Drive Software

- Custom Software Solution

- Design Software

- Engineering Software

- HMI Software

- Industrial Automation Service (Hardware and Software)

- IDEs (Programming Tools)

- Industrial Automation && Products

- Operating System

- PLC Software

- PLC-HMI-SCADA and Automation Training

- SCADA Software

- Server Software

- Unlock PLC HMI

- Skills Training

- About us

- Contact us

- Wishlist

- Automation

Industrial Automation

- Software

- Electrical ProductsElectrical AccessoriesElectrical Devices

- Electronic Products

PC & Accessories

Accessories

Security Devices

- Computer & Accessories

- Industrial Machineries

- Tools & Equipment

- Substation Components

- Shop

- Vendor Registration

- Vendor List

- Articles & News

- EEE and Automation Skills Training

- Training Kit- University-Polytechnic

- AC Drive Software

- Custom Software Solution

- Design Software

- Engineering Software

- HMI Software

- Industrial Automation Service (Hardware and Software)

- IDEs (Programming Tools)

- Industrial Automation && Products

- Operating System

- PLC Software

- PLC-HMI-SCADA and Automation Training

- SCADA Software

- Server Software

- Unlock PLC HMI

- Skills Training

- About us

- Contact us

- Wishlist

- IIOT Device

- Tools & Equipment

- Industrial Machineries

- Software

- Automation

- Load Cell+Controller

- Motorized Valve

- Converter

- Pneumatic Value

- Microwave Motion Sensor

- PLC CPU

- PLC Extension Module

- Delta PLC Extension Module

- ES2-EX-Digital I/O Module

- S series-Digital Input Module

- ES2-EX-Communication Module

- S series-Digital Output Module

- EH3-Analog Input Module

- S series-Analog I/O Module

- EH3-Analog Output Module

- S series-Digital I/O Module

- EH3-Digital Input Module

- S series-Communication Module

- EH3-Digital Output Module

- ES2-EX-Analog Input Module

- EH3-Analog I/O Module

- ES2-EX-Analog Output Module

- EH3-Digital I/O Module

- ES2-EX-Digital Input Module

- EH3-Communication Module

- ES2-EX-Digital Output Module

- S series-Analog Input Module

- ES2-EX-Analog I/O Module

- S series-Analog Output Module

- Mitsubishi PLC Extension Module

- ABB PLC Extension Module

- S7-1200 Temperature Module

- Schneider PLC Extension Module

- Lenz PLC Extension Module

- Siemens PLC Extension Module

- S7-300 Digital I/O Module

- S7-1200 Analog Output Module

- S7-200 Analog I/O Module

- S7-1500 Digital Input Module

- S7-300 Analog Input Module

- S7-1200 Digital Input Module

- S7-200 Temperature Module

- S7-1500 Digital Output Module

- S7-300 Analog Output Module

- S7-1200 Digital Output Module

- Logo Input Module

- S7-1500 Digital I/O Module

- S7-300 Analog I/O Module

- Logo Output Module

- S7-1500 Analog Input Module

- S7-300 Temperature Module

- S7-1200 Communication Module

- Logo Digital I/O Module

- S7-1500 Analog Output Module

- S7-300 Communication Module

- Logo Analog Input Module

- S7-1500 Analog I/O Module

- S7-200 Digital Input Module

- Logo Analog Output Module

- S7-1500 Temperature Module

- S7-200 Digital Output Module

- Logo Analog I/O Module

- S7-1200 Analog I/O Module

- S7-1500 Communication Module

- S7-200 Digital I/O Module

- Logo Temperature Module

- S7-300 Digital Input Module

- S7-200 Analog Input Module

- S7-300 Digital Output Module

- S7-1200 Analog Input Module

- S7-200 Analog Output Module

- Delta PLC Extension Module

- Proximity Sensor

- Industrial Router

- HMI

- Pressure Sensor

- SIMATIC S7-1500 Front connector

- AC DRIVE

- Data Cable

- PT -100 Sensor

- Level Sensor

- SERVO DRIVE+MOTOR

- Second/Minute Timer

- Ultrasonic Sensor

- STEPPER DRIVE+MOTOR

- AC/DC Relay

- Inductive Sensor

- Encoder

- Solid State Relay

- Power Supply

- Photoelectric Sensor

- Counter

- Temperature Controller

- Electrical Products

- Electronic Products

- Substation Components

- Computer & Accessories

- Garments Accessories

- Sorry, this product cannot be purchased.

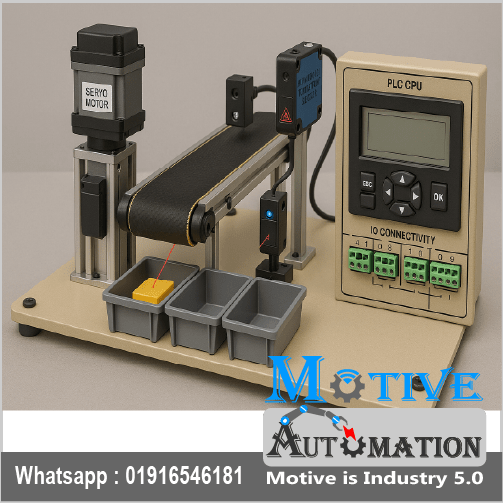

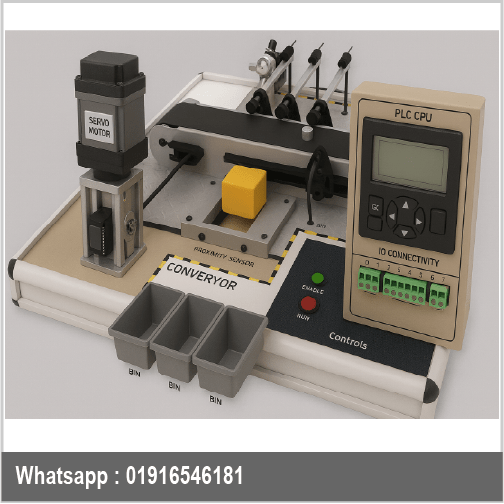

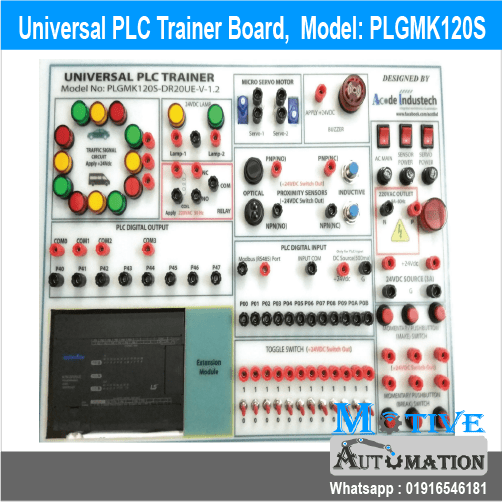

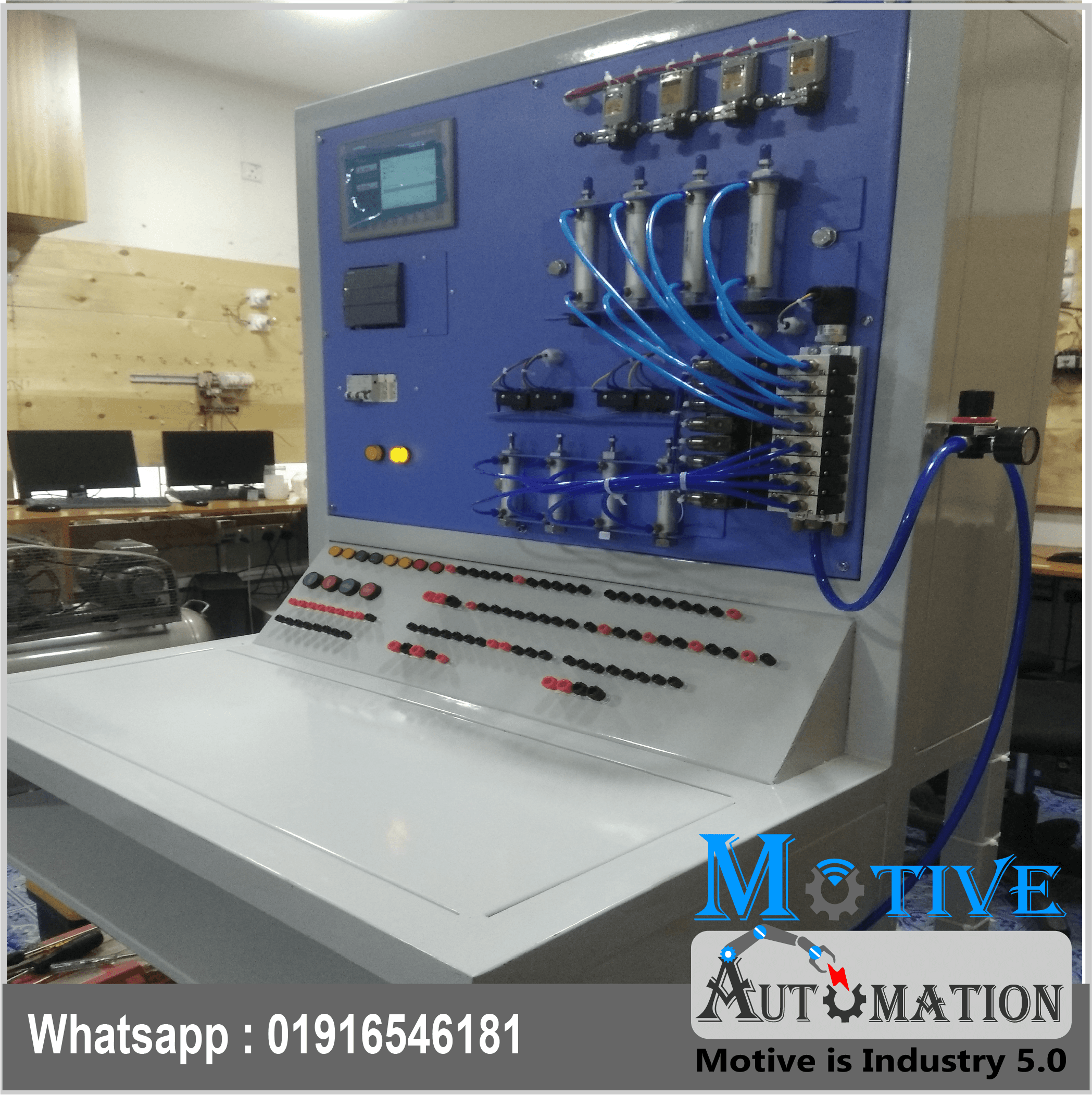

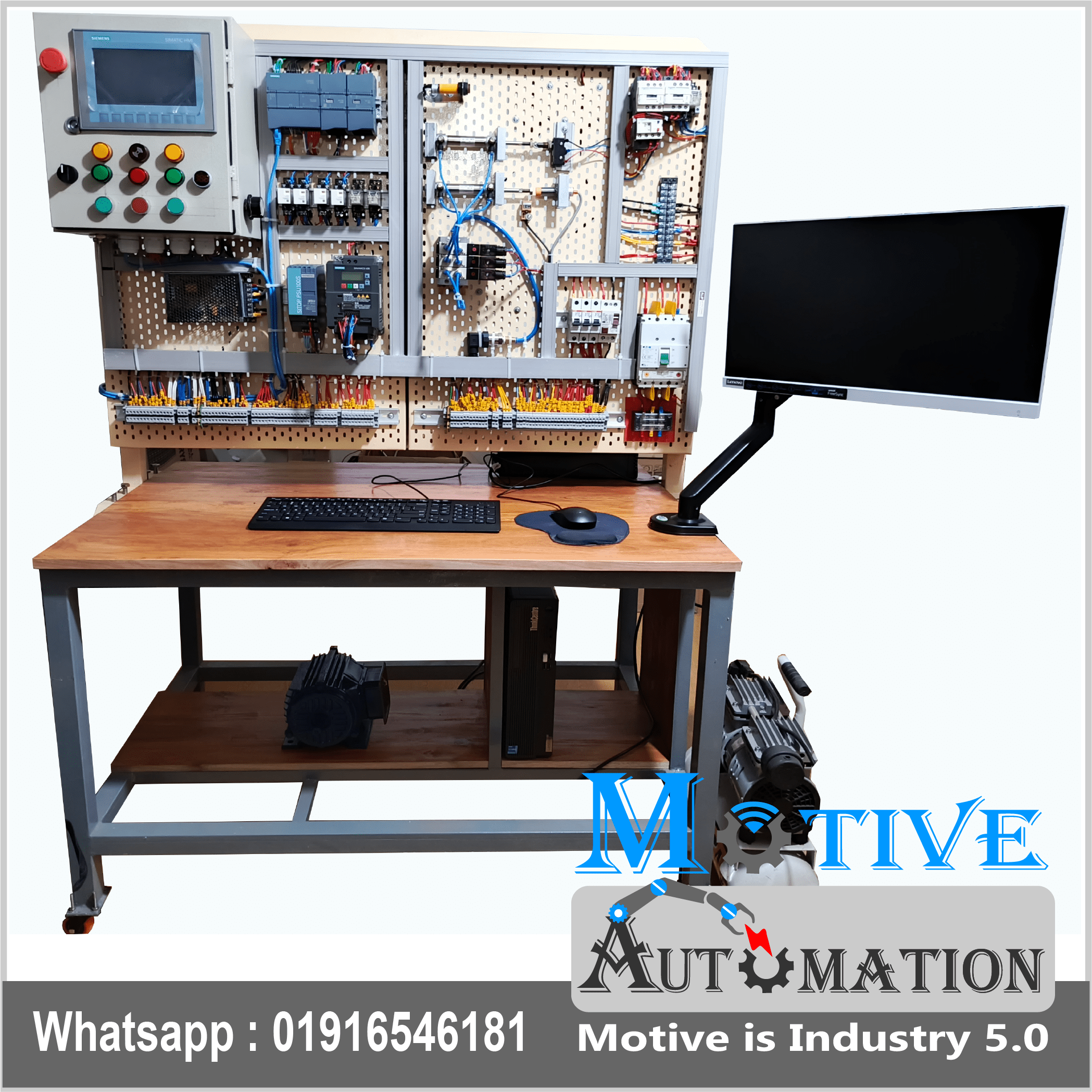

Industrial Conveyor Trainer Kit

৳ 450,000.00

Model: MBD.ICTK.

v001.5

Brand: Motive, BD

Technical Specification:

(Mechanical Size:32”x24”x6”)

,

Motive BD

,

,

Motive BD

,

🔧 Key Features – Industrial Conveyor Trainer Kit

✅ PLC-Based Conveyor Control

— Operated with Siemens S7-1200 PLC for industrial-grade automation.

— Supports multiple conveyor logic modes (manual, automatic, and error

simulation).

✅ Servo Motor Drive System

— 24 V DC industrial servo motor with PLC-compatible control card.

— PWM speed control for adjustable conveyor speed.

✅ Product Detection & Counting

— High-accuracy proximity sensor for product counting.

— Real-time count display on digital counter and HMI.

✅ Non-Contact Temperature Measurement

— Infrared laser temperature sensor with RS-485 Modbus RTU communication.

— HMI display of live product surface temperature.

✅ Error Detection & Indication

— Audio alert via industrial buzzer.

— Visual fault indication using LED signal lamp.

— Simulated fault modes for training (sensor fail, temperature over-limit, jam

detection).

✅ HMI Integration

— Touch-based HMI for live monitoring and control.

— Display of conveyor speed, product count, and temperature data.

✅ PROFINET & Modbus Communication

— Supports PROFINET for PLC-HMI networking.

— Modbus RTU integration for RS-485 temperature sensor.

✅ Safety & Emergency Control

— Emergency stop pushbutton with relay-based safety logic.

— Overload and over-temperature protection.

🎓 Learning Outcomes

• Understand PLC-based conveyor

automation principles.

• Learn servo motor control with PWM and PLC integration.

• Program and configure product counting logic using proximity sensors.

• Acquire skills in RS-485 Modbus sensor communication and data handling.

• Design HMI screens for conveyor monitoring and control.

• Implement fault detection, alarms, and safety interlocks.

• Gain experience in PROFINET/Modbus industrial communication protocols.

• Apply automation concepts to real-world smart manufacturing scenarios.

Spear

Materials and Equipment

v Controller – Siemens S7-1200 PLC (Fully

programmable, Ethernet/Profinet communication).

v Power Supply – 24 V DC system voltage (with

regulated internal 24 V DC supply for sensors and PLC I/O).

v Drive System – Industrial Servo Motor (24 VDC/

220VAC) with high-torque gear assembly.

v Servo Interface – PLC-compatible servo control

card.

v Speed Control – Servo PWM speed controller for

conveyor speed adjustment.

v Product Counting Sensor – Inductive or

capacitive proximity sensor (NPN/PNP, 24 V DC).

v Product Temperature Sensor – Non-contact

infrared laser temperature sensor with RS-485 Modbus RTU output (Configurable

address, baud rate).

v Digital Counter Display – 7-segment or LCD type,

4–6 digits, for real-time product count (supports reset).

v Error Indication – Audio – 24 V DC industrial

buzzer for fault alerts.

v Error Indication – Visual – 24 V DC LED signal

lamp (Red for error, Green for normal operation).

v Safety Features – Emergency stop pushbutton,

overload protection.

Shipping Policy

1. Order Processing Time

- All orders are processed within 1-3 business days (excluding weekends and holidays). We'll do our best to ship your items as soon as possible.

2. Shipping Rates and Delivery Times

- We offer various shipping options at competitive rates. Shipping costs are calculated based on the weight, size, and destination of your order.

- Standard Shipping: [200/= TAKA within Dhaka, Gazipur and Savar City (1-5 KG)]

- Express Shipping: [500/= TAKA within Dhaka, Gazipur, Savar (1-10 KG)]

3. Shipment Tracking

- We provide tracking information for all orders. You will receive an email with a tracking number as soon as your order is shipped, allowing you to monitor the status of your shipment.

4. Shipping Locations

- We currently ship to [Dhaka, Gazipur, SAVAR]. If your location is not on the list, please contact our customer support team to discuss potential shipping options.

5. Shipping Carriers

- We work with trusted carriers to ensure your order reaches you safely and on time. Common carriers we use include [Motive Automation Self Carrier Team].

6. Shipping Restrictions

- Some products may have shipping restrictions due to their nature, regulations, or destination. These restrictions will be clearly stated on the product pages.

7. Shipping Delays

- While we make every effort to deliver your orders on time, please understand that external factors (e.g., weather conditions, customs delays) may occasionally cause shipping delays. We appreciate your patience in such situations.

8. Lost or Stolen Packages

- If your order is marked as delivered but you haven't received it, please contact our customer support team. We will investigate the matter and work to resolve it promptly.

9. Shipping Fees

- Shipping fees are non-refundable, except in cases of incorrect or damaged items. If you receive a damaged product, please review our Return Policy for instructions on returns and refunds.

Refund Policy

1. Returns and Exchanges

- We accept returns and exchanges within [3 working] days from the date of purchase. If [Motive Automation] made an error with your order, such as sending the wrong item, we will cover all return shipping costs. If the return is due to a customer error or preference, the customer is responsible for return shipping costs.

2. Eligibility for Returns and Exchanges

- To be eligible for a return or exchange, items must be in their original condition and packaging, including all tags and labels.

3. Non-Returnable Items

- Certain items are non-returnable, including but not limited to: [VFD- SERVO-SENSOR].

4. Return Process

- To initiate a return or exchange, please contact our customer support team at [+8801916546181]. We will provide you with instructions on how to return your item. Make sure to include your order number and a clear reason for the return.

5. Refunds

- Once your return is received and inspected, we will notify you of the approval or rejection of your refund. If approved, your refund will be processed, and a credit will be automatically applied to your original method of payment within [25] days. Refunds typically take [40] business days to reflect on your account.

6. Exchanges

- If you'd like to exchange an item, please contact our customer support team. We will guide you through the exchange process and ensure you receive the desired product.

7. Damaged or Incorrect Items

- If you receive a damaged or incorrect item, please contact us within [+8801916546181] days of receiving the order. We will promptly replace the item or provide a full refund, including return shipping costs, if applicable.

8. Contact Us

If you have any questions or concerns about our return policy or a specific return/exchange request, please don't hesitate to contact our customer support team. We are here to assist you!

Cancellation / Return / Exchange Policy

Thank you for shopping at [Motive Automation]. We strive to provide you with a positive shopping experience and are committed to ensuring your satisfaction. Please review our combined policy on cancellations, returns, and exchanges.

1. Cancellation Policy

1.1 Order Cancellation

- You may request to cancel your order within [72] hours of placing it, provided that the order has not been processed or shipped. To cancel your order, please contact our customer support team at [+8801916546181].

2. Return and Exchange Policy

2.1 Returns and Exchanges

- We accept returns and exchanges within [03] days from the date of purchase. If [Motive Automation] made an error with your order, such as sending the wrong item or a damaged product, we will cover all return shipping costs. If the return is due to a customer error or preference, the customer is responsible for return shipping costs.

2.2 Eligibility for Returns and Exchanges

- To be eligible for a return or exchange, items must be in their original condition and packaging, including all tags and labels.

2.3 Non-Returnable Items

- Certain items are non-returnable, including but not limited to: [VFD-Servo-Sensor].

2.4 Return Process

- To initiate a return or exchange, please contact our customer support team at [See Customer Support Contact Information]. We will provide you with instructions on how to return your item. Make sure to include your order number and a clear reason for the return.

2.5 Refunds

- Once your return is received and inspected, we will notify you of the approval or rejection of your refund. If approved, your refund will be processed, and a credit will be automatically applied to your original method of payment within [25] days. Refunds typically take [40] business days to reflect on your account.

2.6 Exchanges

- If you'd like to exchange an item, please contact our customer support team. We will guide you through the exchange process and ensure you receive the desired product.

2.7 Damaged or Incorrect Items

- If you receive a damaged or incorrect item, please contact us within [03] days of receiving the order. We will promptly replace the item or provide a full refund, including return shipping costs, if applicable.

3. Contact Us

If you have any questions or concerns about our cancellation, return, or exchange policy, or if you wish to initiate any of these processes, please don't hesitate to contact our customer support team. We are here to assist you!

[+8801916546181]

4. Changes to Policy

[Your Online Store Name] reserves the right to update and modify this policy at any time. Any changes will be posted on our website, and the revised policy will be effective immediately.

By making a purchase on our website, you agree to accept our combined cancellation, return, and exchange policy as stated herein.

Thank you for choosing [Your Online Store Name] for your shopping needs. We appreciate your business!

General Inquiries

There are no inquiries yet.

Related products

Digital Logic Trainer Kit

৳ 22,000.008086 Microprocessor Trainer Ki...

৳ 140,000.00Motor Training Equipment, MTE-...

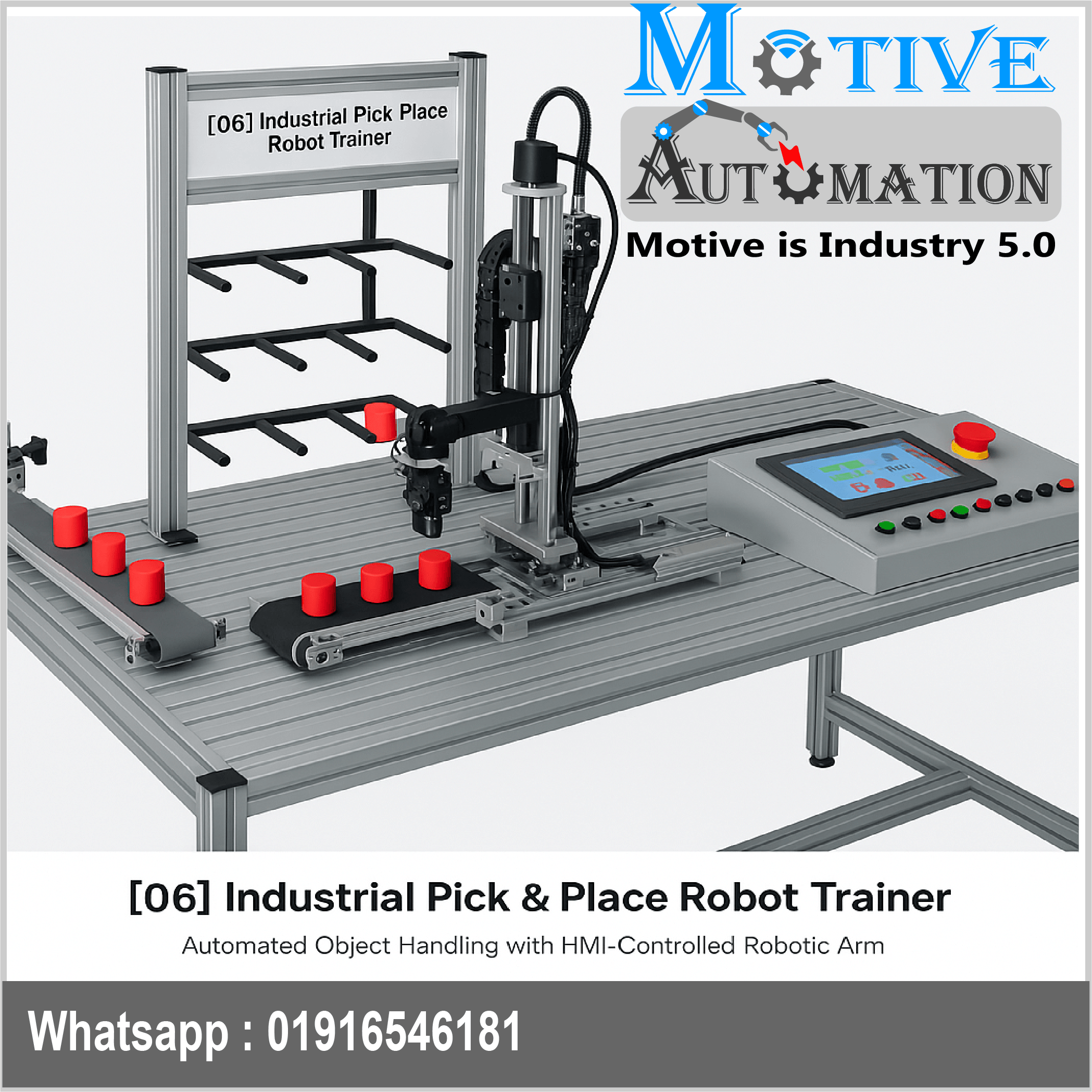

৳ 400,000.00Industrial Pic & Place Ro...

৳ 1,050,000.00Microcontroller Trainer Kit

৳ 35,000.00PC Based Digital Oscilloscope

IoT & HMI Based Industria...

৳ 800,000.003-in-1 Digital Oscilloscope &#...

Electric Trainer Kit Model: DO...

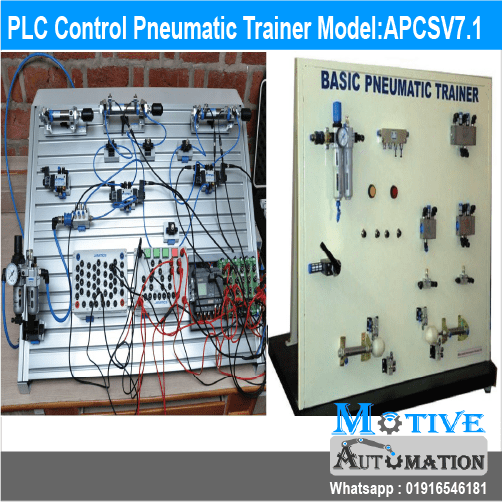

৳ 40,000.00PLC Control Pneumatic Trainer ...

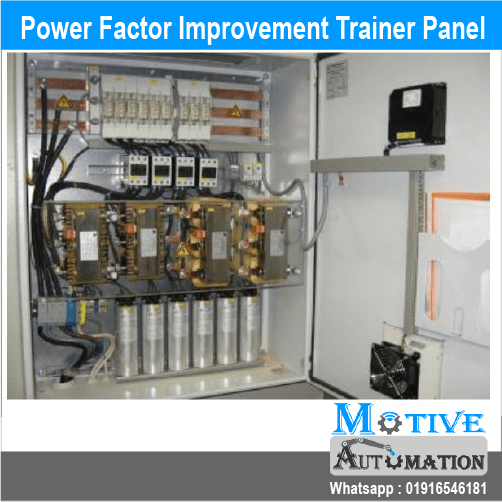

৳ 150,000.00Power Factor Improvement Train...

৳ 140,000.003-IN-1 digital oscilloscope &#...

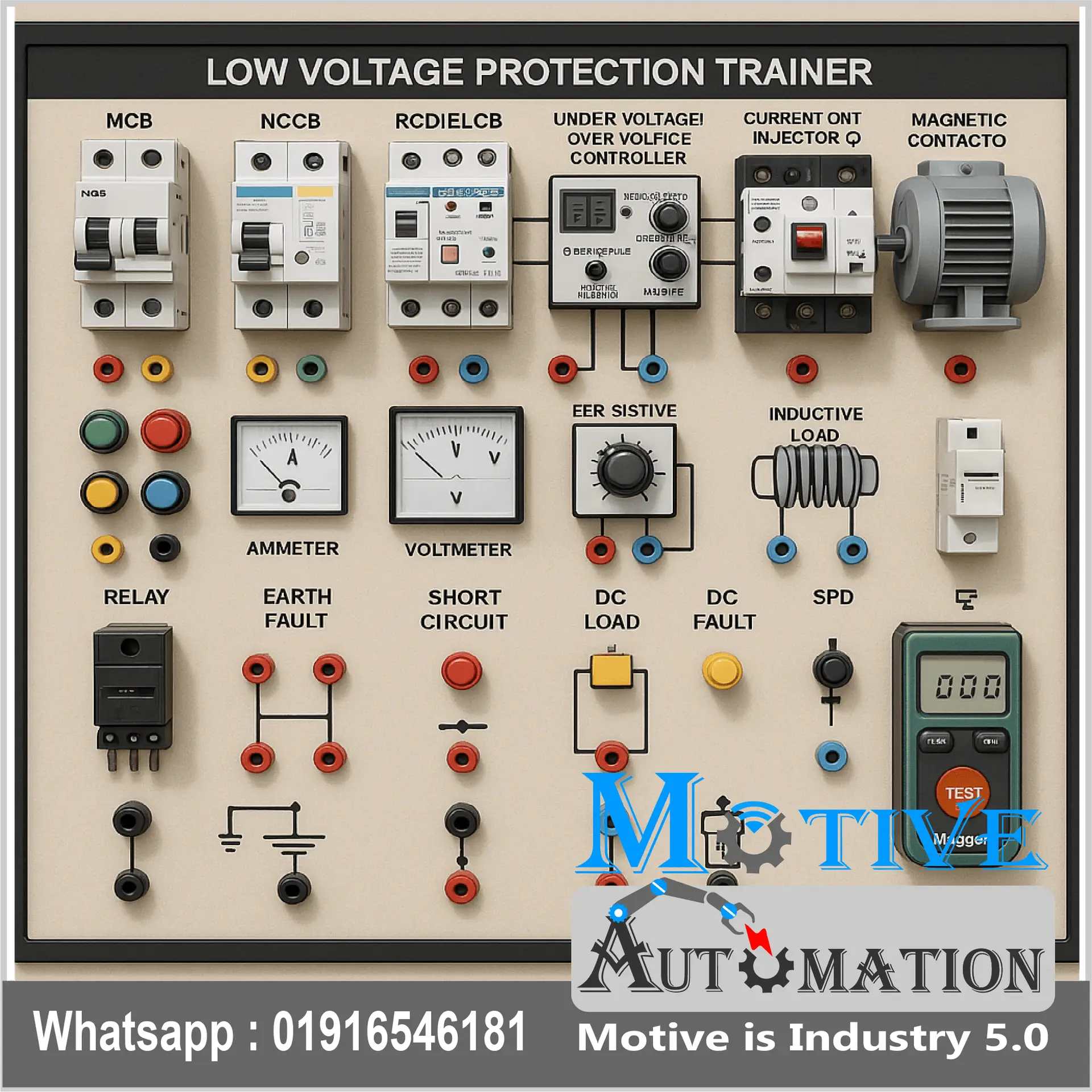

Low Voltage Protection Trainer

৳ 450,000.00LS XGB PLC Trainer Board

৳ 85,000.00Copper wire stripper varnish r...

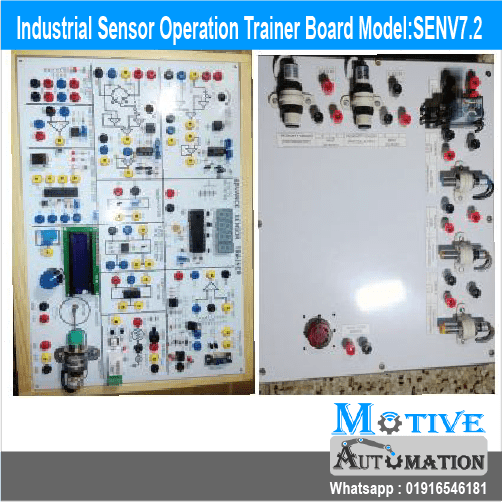

Industrial Sensor Operation Tr...

৳ 120,000.00SIEMENS LOGO PLC Trainer Board...

৳ 65,000.00IoT-Based Advanced PLC-SCADA T...

৳ 980,000.00Advanced PLC Trainer All-in-On...

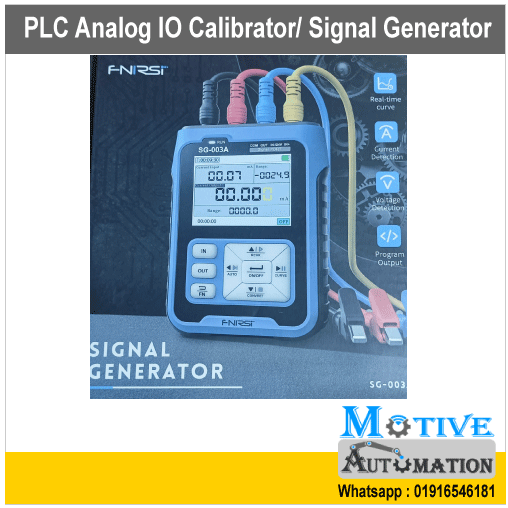

৳ 950,000.00PLC-Analog-IO-Calibrator

৳ 85,000.00

৳ 65,000.00

Reviews

There are no reviews yet.