- Shop

- Vendor Registration

- Vendor List

- Articles & News

- EEE and Automation Skills Training

- Training Kit- University-Polytechnic

- AC Drive Software

- Custom Software Solution

- Design Software

- Engineering Software

- HMI Software

- Industrial Automation Service (Hardware and Software)

- IDEs (Programming Tools)

- Industrial Automation && Products

- Operating System

- PLC Software

- PLC-HMI-SCADA and Automation Training

- SCADA Software

- Server Software

- Unlock PLC HMI

- Skills Training

- About us

- Contact us

- Wishlist

- Automation

Industrial Automation

- Software

- Electrical ProductsElectrical AccessoriesElectrical Devices

- Electronic Products

PC & Accessories

Accessories

Security Devices

- Computer & Accessories

- Industrial Machineries

- Tools & Equipment

- Substation Components

- Shop

- Vendor Registration

- Vendor List

- Articles & News

- EEE and Automation Skills Training

- Training Kit- University-Polytechnic

- AC Drive Software

- Custom Software Solution

- Design Software

- Engineering Software

- HMI Software

- Industrial Automation Service (Hardware and Software)

- IDEs (Programming Tools)

- Industrial Automation && Products

- Operating System

- PLC Software

- PLC-HMI-SCADA and Automation Training

- SCADA Software

- Server Software

- Unlock PLC HMI

- Skills Training

- About us

- Contact us

- Wishlist

- Automation

- Microwave Motion Sensor

- PLC CPU

- PLC Extension Module

- ABB PLC Extension Module

- S7-1200 Temperature Module

- Schneider PLC Extension Module

- Lenz PLC Extension Module

- Siemens PLC Extension Module

- S7-1200 Digital Output Module

- Logo Input Module

- S7-1500 Digital I/O Module

- S7-300 Analog I/O Module

- Logo Output Module

- S7-1500 Analog Input Module

- S7-300 Temperature Module

- S7-1200 Communication Module

- Logo Digital I/O Module

- S7-1500 Analog Output Module

- S7-300 Communication Module

- Logo Analog Input Module

- S7-1500 Analog I/O Module

- S7-200 Digital Input Module

- Logo Analog Output Module

- S7-1500 Temperature Module

- S7-200 Digital Output Module

- S7-1200 Analog I/O Module

- Logo Analog I/O Module

- S7-1500 Communication Module

- S7-200 Digital I/O Module

- Logo Temperature Module

- S7-300 Digital Input Module

- S7-200 Analog Input Module

- S7-300 Digital Output Module

- S7-1200 Analog Input Module

- S7-200 Analog Output Module

- S7-300 Digital I/O Module

- S7-1200 Analog Output Module

- S7-200 Analog I/O Module

- S7-1500 Digital Input Module

- S7-300 Analog Input Module

- S7-1200 Digital Input Module

- S7-200 Temperature Module

- S7-1500 Digital Output Module

- S7-300 Analog Output Module

- Delta PLC Extension Module

- S series-Analog I/O Module

- EH3-Analog Output Module

- S series-Digital I/O Module

- EH3-Digital Input Module

- S series-Communication Module

- EH3-Digital Output Module

- ES2-EX-Analog Input Module

- EH3-Analog I/O Module

- ES2-EX-Analog Output Module

- EH3-Digital I/O Module

- ES2-EX-Digital Input Module

- EH3-Communication Module

- ES2-EX-Digital Output Module

- S series-Analog Input Module

- ES2-EX-Analog I/O Module

- S series-Analog Output Module

- ES2-EX-Digital I/O Module

- S series-Digital Input Module

- ES2-EX-Communication Module

- S series-Digital Output Module

- EH3-Analog Input Module

- Mitsubishi PLC Extension Module

- Industrial Router

- Proximity Sensor

- HMI

- SIMATIC S7-1500 Front connector

- Pressure Sensor

- AC DRIVE

- PT -100 Sensor

- Data Cable

- Level Sensor

- SERVO DRIVE+MOTOR

- Second/Minute Timer

- Ultrasonic Sensor

- STEPPER DRIVE+MOTOR

- AC/DC Relay

- Inductive Sensor

- Encoder

- Power Supply

- Solid State Relay

- Photoelectric Sensor

- Counter

- Temperature Controller

- Load Cell+Controller

- Converter

- Motorized Valve

- Pneumatic Value

- Electrical Products

- Electronic Products

- Substation Components

- Computer & Accessories

- Garments Accessories

- IIOT Device

- Tools & Equipment

- Industrial Machineries

- Software

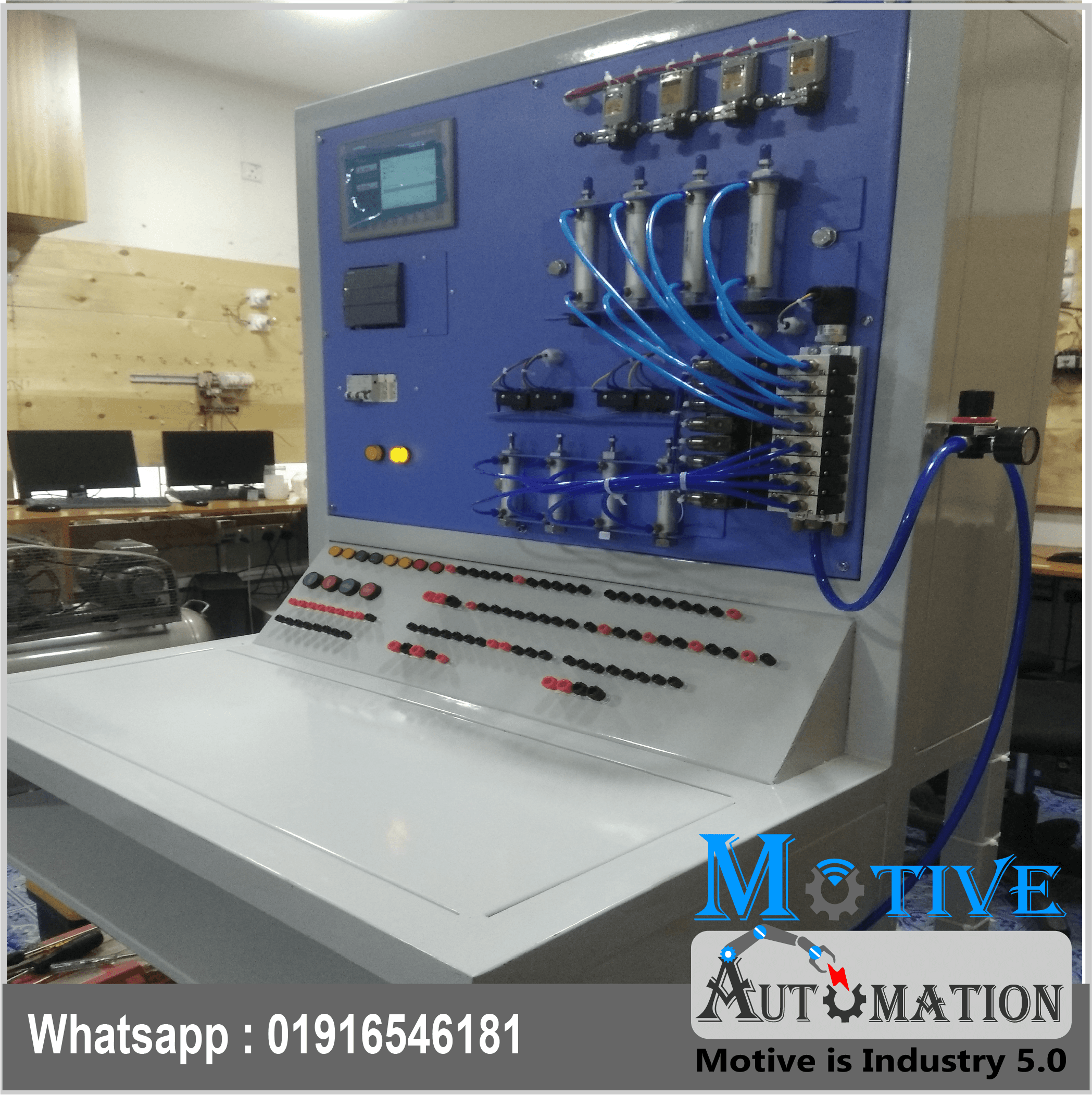

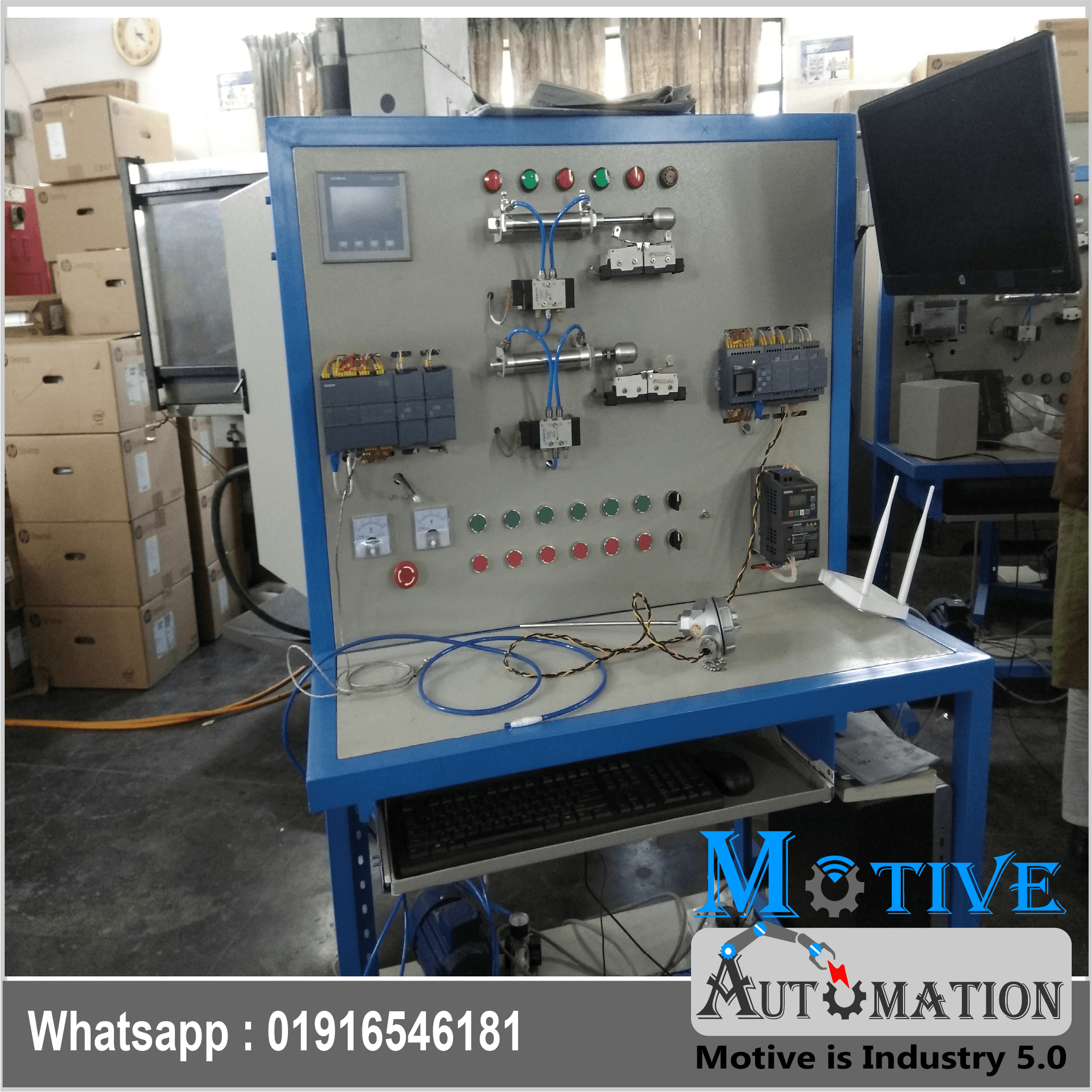

IoT-Based Advanced PLC-SCADA Trainer Board

৳ 980,000.00

Model: MBD.S7.APSTB.4ir002.25

Brand: Motive, BD

✅ Advanced PLC

System

✅ SCADA

Integration

✅ IoT

Connectivity

✅ Sensor &

Actuator Interface

✅ Remote

Monitoring

✅ Data Logging

& Analytics

,

,

,

Motive BD

,

,

Motive BD

,

The IoT-Based Advanced PLC-SCADA Trainer Board is a state-of-the-art educational platform designed to bridge the gap between industrial automation and Industry 4.0 technologies. It provides practical training in PLC programming, SCADA monitoring, and Industrial Internet of Things (IoT) applications.

🔧Key Features:

✅ Advanced PLC System – Equipped with industry-standard PLCs (Siemens, Allen-Bradley, or Delta) for real-time automation logic implementation.

✅ SCADA Integration – Includes SCADA software for real-time monitoring, data acquisition, and control of industrial processes.

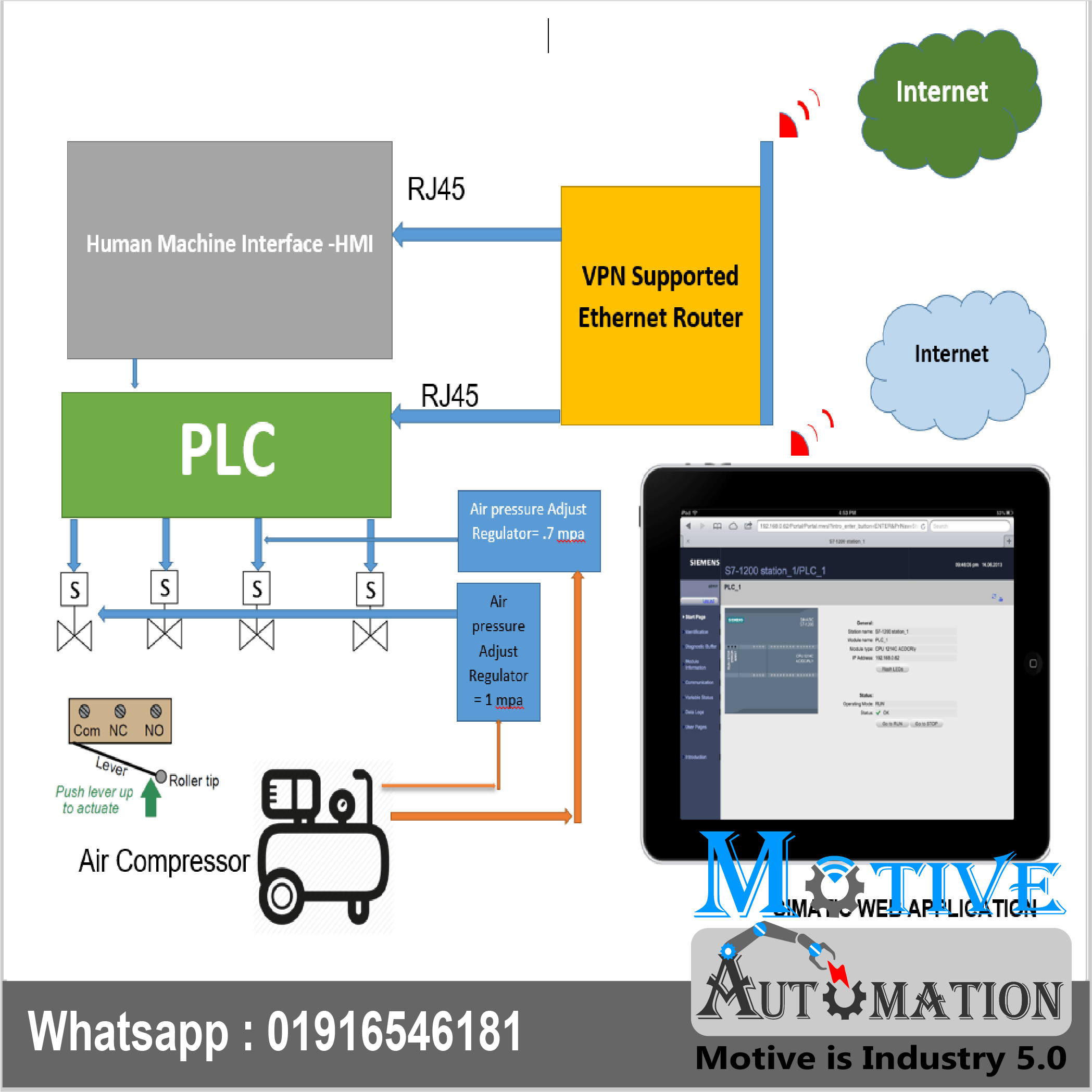

✅ IoT Connectivity – Enables data transmission via Ethernet, MQTT, or Modbus TCP/IP to cloud platforms or local HMI/SCADA systems.

✅ Sensor & Actuator Interface – Supports integration with various sensors (temperature, pressure, proximity) and actuators (relays, contactors, motors) for simulation of real-world processes.

✅ Remote Monitoring – Access and control the system from anywhere using a secure network interface—mimicking smart factory operations.

✅ Data Logging & Analytics – Collects and stores process data for analysis, improving operational efficiency and predictive maintenance learning.

🎓Educational Benefits:

Develops practical

skills in PLC programming, SCADA design, and IIoT system

integration

Ideal for students

of electrical, electronics, mechatronics, and industrial automation

engineering

Enables

understanding of smart manufacturing, real-time process control,

and remote diagnostics

📦 What’s Included:

PLC-based control

panel

SCADA software with

PC interface

Sensor/actuator

simulation modules

IIoT gateway with

cloud connectivity

Training manuals

and experiment guides

Mejor Device and Spear

Parts Brand

Device and Speare Parts: Origin China

LAB Installation + Programming + Training

🎓 Training Features &

Parameters – Advanced Industrial Automation Trainer Kit

The

system is designed to offer in-depth, hands-on training in modern industrial automation

technologies. Below are the comprehensive features and parameters covered in

the training:

🧠 Basic Logic & Digital

Operations

- Logic Gate

Operations: AND, OR, NOT, NOR, NAND, EX-OR, EX-NOR - LED Digital

Control using Timers and Counters

⚙️ Industrial Motor & Relay Control

- Conventional

Motor Control using Timers and Counters - Industrial Relay

Control with HMI - Motor Control via HMI interface

- Induction Motor Speed (Frequency) Control using PLC analog I/O

- Industrial Robot

Axis Control via onboard Servo System - Servo & Induction Motor RPM Control using IoT Cloud Server

🌐 Communication &

Integration

- PROFINET Communication for real-time industrial networking

- PLC–VFD–HMI PROFINET integration

- Modbus Communication for displaying motor runtime, frequency &

RPM on HMI - Remote Motor Control and Temperature Monitoring via IIoT

- Monitor & Control Pneumatic Valves and Air Pressure using PLC Web Server

🖥️ HMI & SCADA Programming

- HMI Interfacing

with PLC - HMI Programming:

Bit Switch, Bit Lamp, Timer, Counter - Graphical Keyboard for PLC data input

- Industrial Alarm & Error Logging

System via HMI - Temperature Control using HMI & PLC

- Monitor Temperature and Humidity using SIEMENS WinCC RT SCADA

·

IoT Connectivity – Enables data transmission via Ethernet, MQTT, or

Modbus TCP/IP to cloud platforms or local HMI/SCADA systems.

🔧 Analog, Sensor & Signal

Control

- Analog

Operations: ADC, DAC, PWM - Onboard PID

Simulator - Onboard Temperature

& Humidity Sensor - Onboard Proximity

Sensor Modules (Inductive, Capacitive, Photoelectric) - Onboard Pneumatic Cylinder Control

- Onboard Encoder

& High-Speed Pulse Simulator

🎯 Bonus:

Students can engage with over 50+ real-time industrial project simulations,

helping them gain practical insights into modern factory automation, IIoT, and

control systems.

Learning Content and Materials

After adding this trainer board to your automation course, the trainee will be able

to learn the following major tasks:

ü Identify different types of PLC hardware (SIEMENS).

ü Use PLC input/output logically in power system

automation.

ü Create ladder logic for industrial control systems.

ü Program analog input using PLC ladder logic.

ü Program analog output using PLC ladder logic.

ü Program Modbus RTU using PLC ladder logic.

ü Program traffic signal circuits using PLC ladder

logic and HMI hardware.

ü Control power system equipment using PLC.

ü Control and monitor PLC status over the Internet

(IoT).

ü Control and monitor a machine servo axis using

SCADA.

ü Control and monitor industrial temperature using PLC

web server.

ü Create and use proper ladder logic for Siemens

analog input-output and control output load.

ü Configure variable frequency drives and stepper

motors using Siemens PLC & HMI ladder logic.

ü Configure and control an induction motor using PC

SCADA and OPC server.

ü Read and monitor the PID system using PC SCADA and

OPC server.

SCADA Core

ü To Identify different types of industrial SCADA

software.

ü Can Understand why SCADA is used and where it can be

applied.

ü Can Use TIA WINCC Advanced/Professional software.

ü Create a new project in WinCC on a standalone PC.

ü Can Make tags and connections to a PLC using the

S7-PLCSIM simulator.

ü Can Create switches, lamps, indicators, and sliders

using the WINCC Graphics Designer.

ü Configure alarms and display them with proper IP

setting and industrial network security.

ü Can Perform real-world hands-on tasks using WINCC RT

SCADA software.

ü Can Create an MS SQL database and insert data using

the C# .NET library / VBScript.

ü Can Generate reports and printing.

ü Can Configure the OPC UA server and client.

| SL No. | Item Description |

| 1 | Universal Training Table Panel Type Trainer Steel Table, Table Dimension: Table bade: L-48 inch x W-28 inch, Table H- 26inch + 2 inch wheel=4pcs, break type, Table Features: a) Build with PLC panel on the tabletop bead (L48=inch x W=8 inch, h- 28 inch, Table Features: b) Build with 19 inch Monitor and CPU mounting kit, Table Features: c), Build with induction motor mounting paddle, MS- SWG: 18, powder coated, with all necessary, component mounting, cutting and hole, Brand: Motive, Made in BD |

| 2 | Main PLC CPU S7-1200 CPU 1214C-DC/DC/DC Work memory 100 KB; 24VDC power supply with DI14 x 24VDC SINK/SOURCE, DQ10 x 24VDC and AI2 on board; 6 high-speed counters and 4 pulse outputs on-board; signal board expands on-board I/O; up to 3 communication modules for serial communication; up to 8 signal modules for I/O expansion; PROFINET IO controller, I-device, transport protocol TCP/IP, secure Open User Communication, S7 communication, Web server, OPC UA: Server DA Brand: SIEMENS, Made in China |

| 3 | S7-1200 Modbus Module Communications board with RS-485 interface CB 1241 Brand: SIEMENS, Made in China |

| 4 | S7-1200 Analog Input-Output Module SM 1234 AI4/AQ2 Analog input/output module AI4 + AQ2; plug-in terminal blocks; inputs: 13 bits, 2.5V, 5V, 10V and 0/4 to 20 mA; selectable frequency suppression; selectable smoothing; configurable diagnostics; outputs: +/-10V and 0 to 20 mA; configurable diagnostics; configurable substitute value for output Brand: SIEMENS, Made in China |

| 5 | S7-1200 Temperature Input Module SM 1231 AI4 x RTD Brand: SIEMENS, Made in China |

| 6 | Touch Display / HMI (KTP400 BASIC) Design: TFT widescreen display, LED , Operation: Key/touch Display size: 4″ TFT display , PROFINET interface Horizontal image resolution: 480 pixel, Vertical image resolution: 272 pixel Number of function keys: 4 |

| 7 | Induction Motor, 0.75KW, 3phase 440 Brand: SIEMENS / ABB, Made in China |

| AC Servo System Servo Motor + Servo Drive Capacity: 400 W, Input: 1phase 220VAC, RPM 10- 3000 Brand: Delta, Made in China |

|

| 8 | Variable Frequency Driver SINAMIC V20 phases: 3 AC o Rated power: 1.5kW, 3phase 440VAC Brand: SIEMENS, Made in China |

| 9 | IoT Gateway 4G/5G LTE VPN Cellular Router, LTE Cat 4+ Wi-Fi, Dual sim Card Slots, Management by Cloud Platform, DI/DO Port, Support T-Mobile, AT&T & Verizon, UL Certification, Brand: InHand, Made in China |

| 10 | Pressure Transmitter 0-10 bar, 4-20mA, DC 10-30V Brand: WIKA, Made in China |

| 11 | Proximity Sensor Inductive – 1pcs Capacitive – 1pcs Photoelectric – 2pcs PNP-NPN- 24vdc Brand: Autonics, Made in China |

| 12 | Pneumatic Cylinder Size: 32 x 100 32mm Bore 100mm Stroke. = 4pcs (SMC) Pneumatic Actuator = 24vdc = 4pcs (AirTAC) Air pressure Control Regulator = 1pcs Limit Switch = 4pcs Brand: China, Made in China |

| 13 | Air Compressor Max Pressure: 10bar/116psi Tank Capacity: 20-30L Frequency: 50-60Hz Speed: 2800RPM Length: 58cm Power: 1HP Voltage: 220-240V Includes: Air Filter, Oil Bottle, 2 air couplers Brand: China, Made in China |

| 14 | Onboard Spear Parts and Fixing Accessories: Control Cable: 0.5 rm = 2coil Power Cable: 2rm = 40 yards Relay 24vdc, 14pin= 6pcs Power Supply 24vdc, 5A=2pcs MCB, 16A = 4pcs MCB, 32A= 1pcs RTC Fuse2A= 2pcs Push Switch=6pcs Toggle Switch=6pcs Rotatory encoder= 1pcs Magnetic Contact = 2pcs Safety Laboratory Socket = as per need And plug = R,Y, G,B = 40pcs Cable tie and cable lugs Brand: China, Made in China |

| 15 | Intel 12th Gen Core i5-12400 Desktop PC Brand INTEL Key Features Model: 10th Gen Desktop PC Intel 10th Gen Core i5-12400 Alder Lake Processor MSI PRO H610M-E DDR4 mATX Motherboard Corsair Vengeance LPX 16GB 3200MHz DDR4 Desktop RAM HP EX900 PLUS 256GB M.2 PCIe NVMe Internal SSD 1tb HDD Monitor 19 inch wide Including SIEMENS TIA Portal V19 Licensed Software and Router: TP link Brand: Intel (PC) Brand: HIKVISION (Monitor) Brand: SIEMENS (PLC-SCADA Software) |

General Inquiries

There are no inquiries yet.

Related products

INVT-VFD-2.2KW,3HP,5.5A

৳ 18,400.00S7-1500, Rail, 830MM

INVT-VFD-200KW,270HP,380A-GD20...

INVT-VFD-132KW,200HP,260A-GD20...

INVT-VFD-1.5KW,2HP,4.2A

৳ 16,675.00S7-1500 Front connector in pus...

৳ 9,500.00INVT-VFD-75KW,100HP,150A-GD20-...

INVT-VFD-280KW,350HP,530A-GD20...

S7-1200 CM 1241 (RS422/485)

৳ 11,000.00INVT-VFD-37KW,50HP,75A-GD20-03...

INVT-VFD-7.5KW,10HP,18.5A

৳ 38,755.00Power Supply 400 VAC – 2...

৳ 30,000.00INVT-VFD-5.5KW,7.5HP,20A

৳ 33,005.00INVT-VFD-2.2KW,2HP,7.5A

৳ 19,780.00S7-1500, DI 32x24VDC HF_1

৳ 54,500.00S7-1500, CPU 1511-1 PN-6ES7 51...

৳ 180,000.00INVT-VFD-7.5KW,10HP,30A

৳ 38,755.00INVT-VFD-0.75KW,1HP,2.5A

৳ 14,950.00S7-1500,CPU 1511C-1 PN

৳ 250,000.00CPU 1214C AC/DC/Rly

৳ 50,000.00INVT-VFD-0.75KW,1HP,4.2A

৳ 12,650.00INVT-VFD-4.0KW,5.4HP,9.5A

৳ 23,000.00INVT-VFD-18KW,25HP,38A-GD20-01...

৳ 10,080.00INVT-VFD-250KW,335HP,480A-GD20...

৳ 17,500.00

৳ 1,050,000.00

Reviews

There are no reviews yet.