- Shop

- Vendor Registration

- Vendor List

- Articles & News

- EEE and Automation Skills Training

- Training Kit- University-Polytechnic

- AC Drive Software

- Custom Software Solution

- Design Software

- Engineering Software

- HMI Software

- Industrial Automation Service (Hardware and Software)

- IDEs (Programming Tools)

- Industrial Automation && Products

- Operating System

- PLC Software

- PLC-HMI-SCADA and Automation Training

- SCADA Software

- Server Software

- Unlock PLC HMI

- Skills Training

- About us

- Contact us

- Wishlist

- Automation

Industrial Automation

- Software

- Electrical ProductsElectrical AccessoriesElectrical Devices

- Electronic Products

PC & Accessories

Accessories

Security Devices

- Computer & Accessories

- Industrial Machineries

- Tools & Equipment

- Substation Components

- Shop

- Vendor Registration

- Vendor List

- Articles & News

- EEE and Automation Skills Training

- Training Kit- University-Polytechnic

- AC Drive Software

- Custom Software Solution

- Design Software

- Engineering Software

- HMI Software

- Industrial Automation Service (Hardware and Software)

- IDEs (Programming Tools)

- Industrial Automation && Products

- Operating System

- PLC Software

- PLC-HMI-SCADA and Automation Training

- SCADA Software

- Server Software

- Unlock PLC HMI

- Skills Training

- About us

- Contact us

- Wishlist

- Garments Accessories

- IIOT Device

- Tools & Equipment

- Industrial Machineries

- Software

- Automation

- Load Cell+Controller

- Motorized Valve

- Converter

- Pneumatic Value

- Microwave Motion Sensor

- PLC CPU

- PLC Extension Module

- Siemens PLC Extension Module

- S7-300 Digital Output Module

- S7-1200 Analog Input Module

- S7-200 Analog Output Module

- S7-300 Digital I/O Module

- S7-1200 Analog Output Module

- S7-200 Analog I/O Module

- S7-1500 Digital Input Module

- S7-300 Analog Input Module

- S7-1200 Digital Input Module

- S7-200 Temperature Module

- S7-1500 Digital Output Module

- S7-300 Analog Output Module

- S7-1200 Digital Output Module

- Logo Input Module

- S7-1500 Digital I/O Module

- S7-300 Analog I/O Module

- Logo Output Module

- S7-1500 Analog Input Module

- S7-300 Temperature Module

- S7-1200 Communication Module

- Logo Digital I/O Module

- S7-1500 Analog Output Module

- S7-300 Communication Module

- Logo Analog Input Module

- S7-1500 Analog I/O Module

- S7-200 Digital Input Module

- Logo Analog Output Module

- S7-1500 Temperature Module

- S7-200 Digital Output Module

- Logo Analog I/O Module

- S7-1200 Analog I/O Module

- S7-1500 Communication Module

- S7-200 Digital I/O Module

- Logo Temperature Module

- S7-300 Digital Input Module

- S7-200 Analog Input Module

- Delta PLC Extension Module

- ES2-EX-Analog I/O Module

- S series-Analog Output Module

- ES2-EX-Digital I/O Module

- S series-Digital Input Module

- ES2-EX-Communication Module

- S series-Digital Output Module

- EH3-Analog Input Module

- S series-Analog I/O Module

- EH3-Analog Output Module

- S series-Digital I/O Module

- EH3-Digital Input Module

- S series-Communication Module

- EH3-Digital Output Module

- ES2-EX-Analog Input Module

- EH3-Analog I/O Module

- ES2-EX-Analog Output Module

- EH3-Digital I/O Module

- ES2-EX-Digital Input Module

- EH3-Communication Module

- ES2-EX-Digital Output Module

- S series-Analog Input Module

- Mitsubishi PLC Extension Module

- ABB PLC Extension Module

- S7-1200 Temperature Module

- Schneider PLC Extension Module

- Lenz PLC Extension Module

- Siemens PLC Extension Module

- Proximity Sensor

- Industrial Router

- HMI

- Pressure Sensor

- SIMATIC S7-1500 Front connector

- AC DRIVE

- Data Cable

- PT -100 Sensor

- Level Sensor

- SERVO DRIVE+MOTOR

- Second/Minute Timer

- Ultrasonic Sensor

- STEPPER DRIVE+MOTOR

- AC/DC Relay

- Inductive Sensor

- Encoder

- Solid State Relay

- Power Supply

- Photoelectric Sensor

- Counter

- Temperature Controller

- Electrical Products

- Electronic Products

- Substation Components

- Computer & Accessories

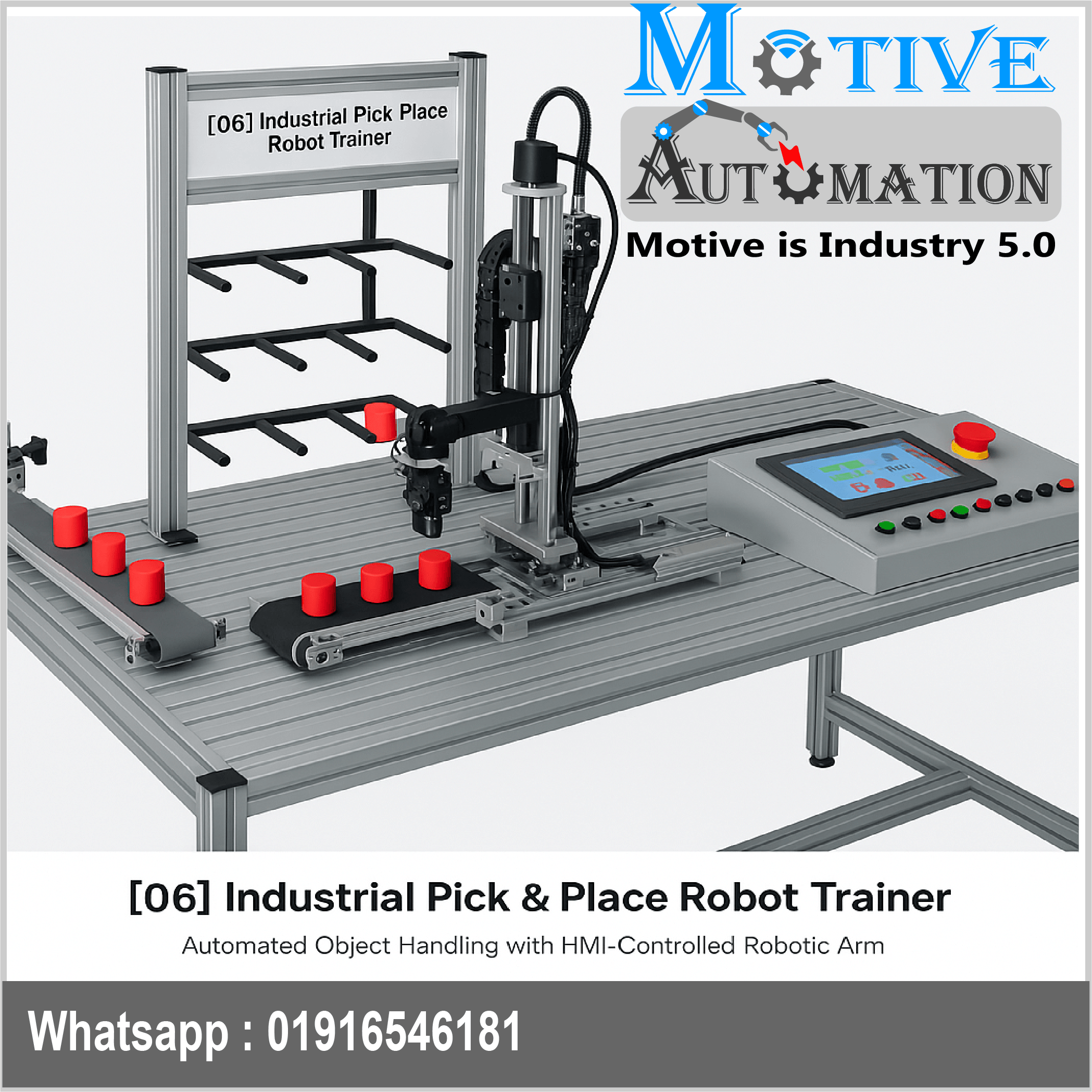

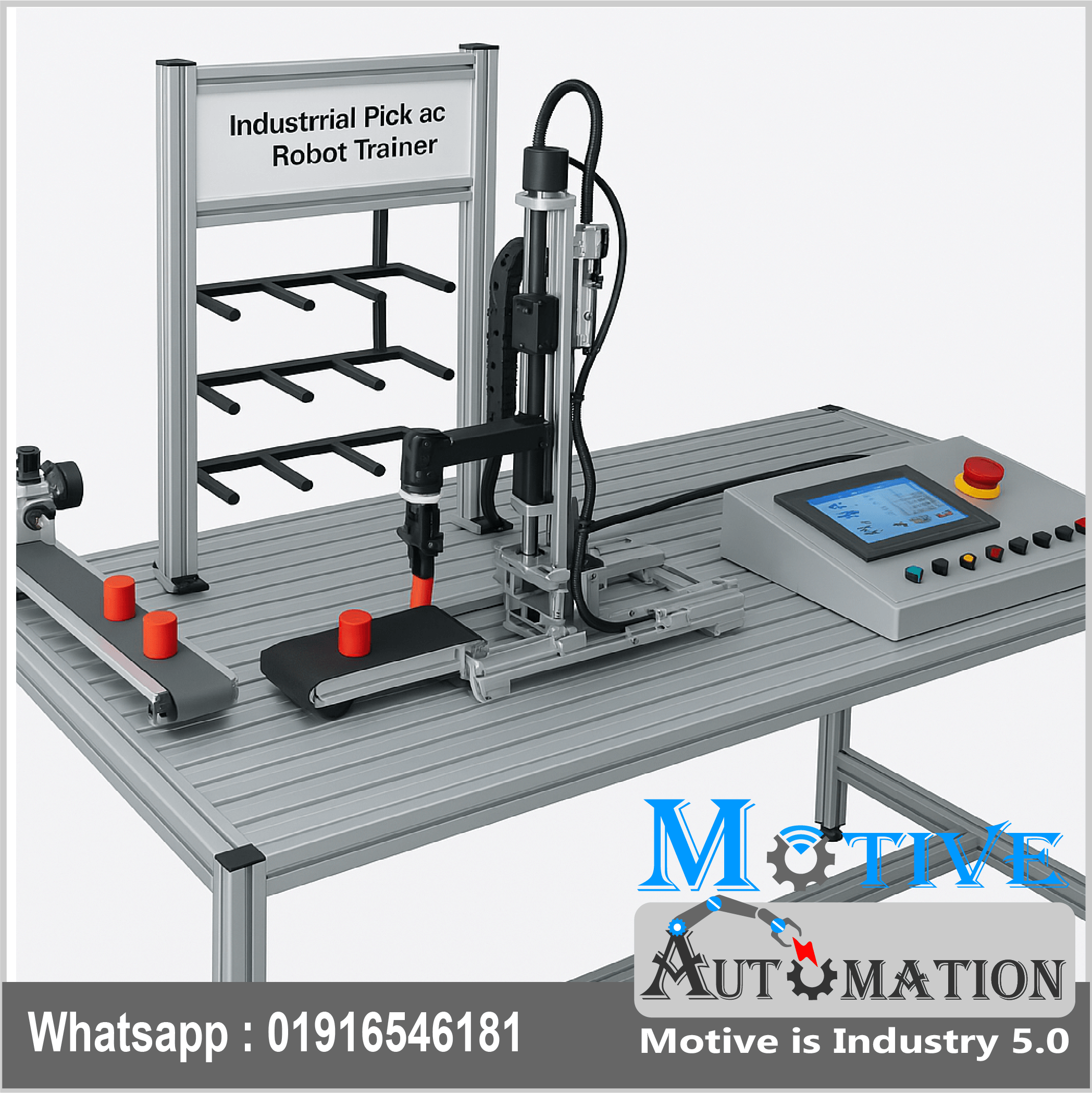

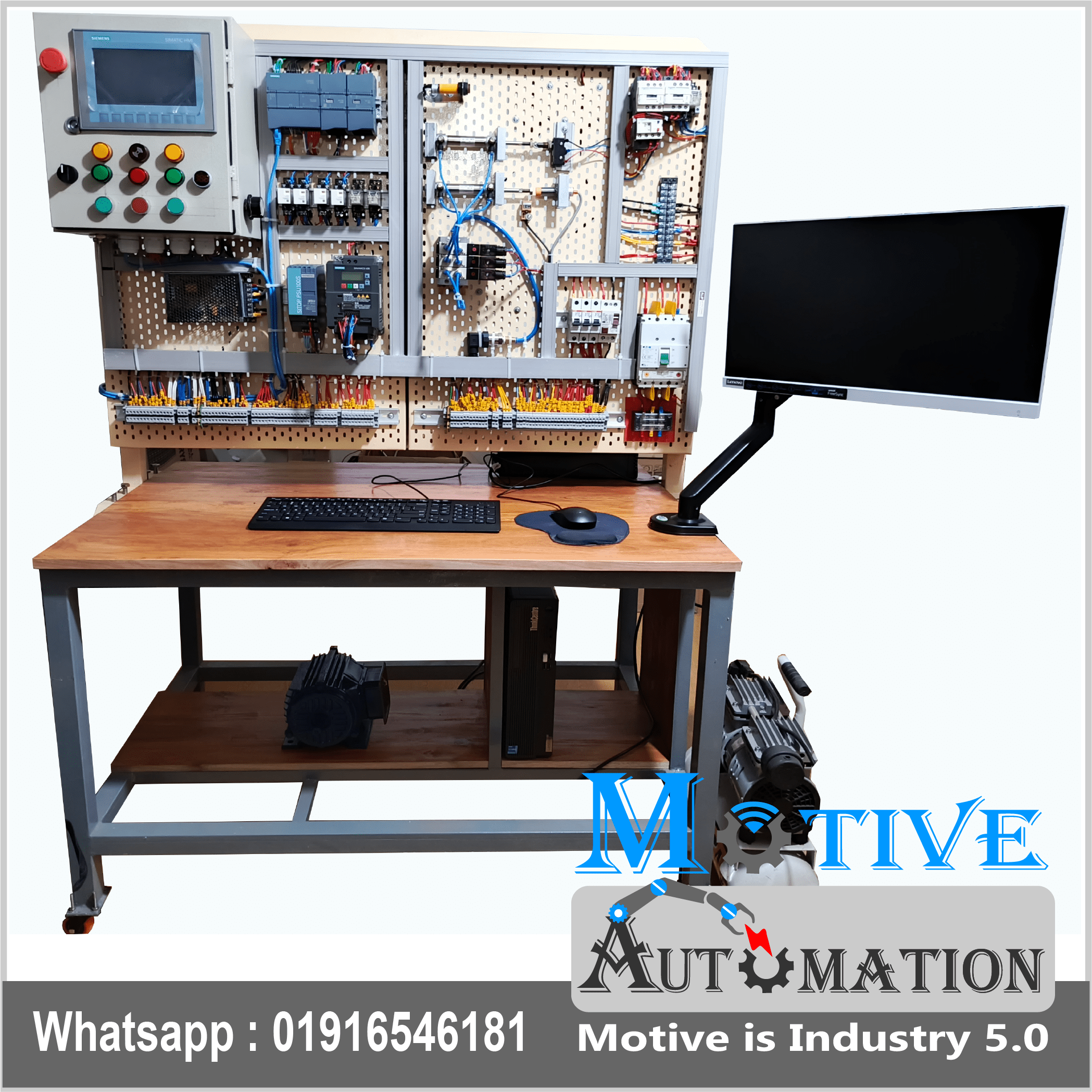

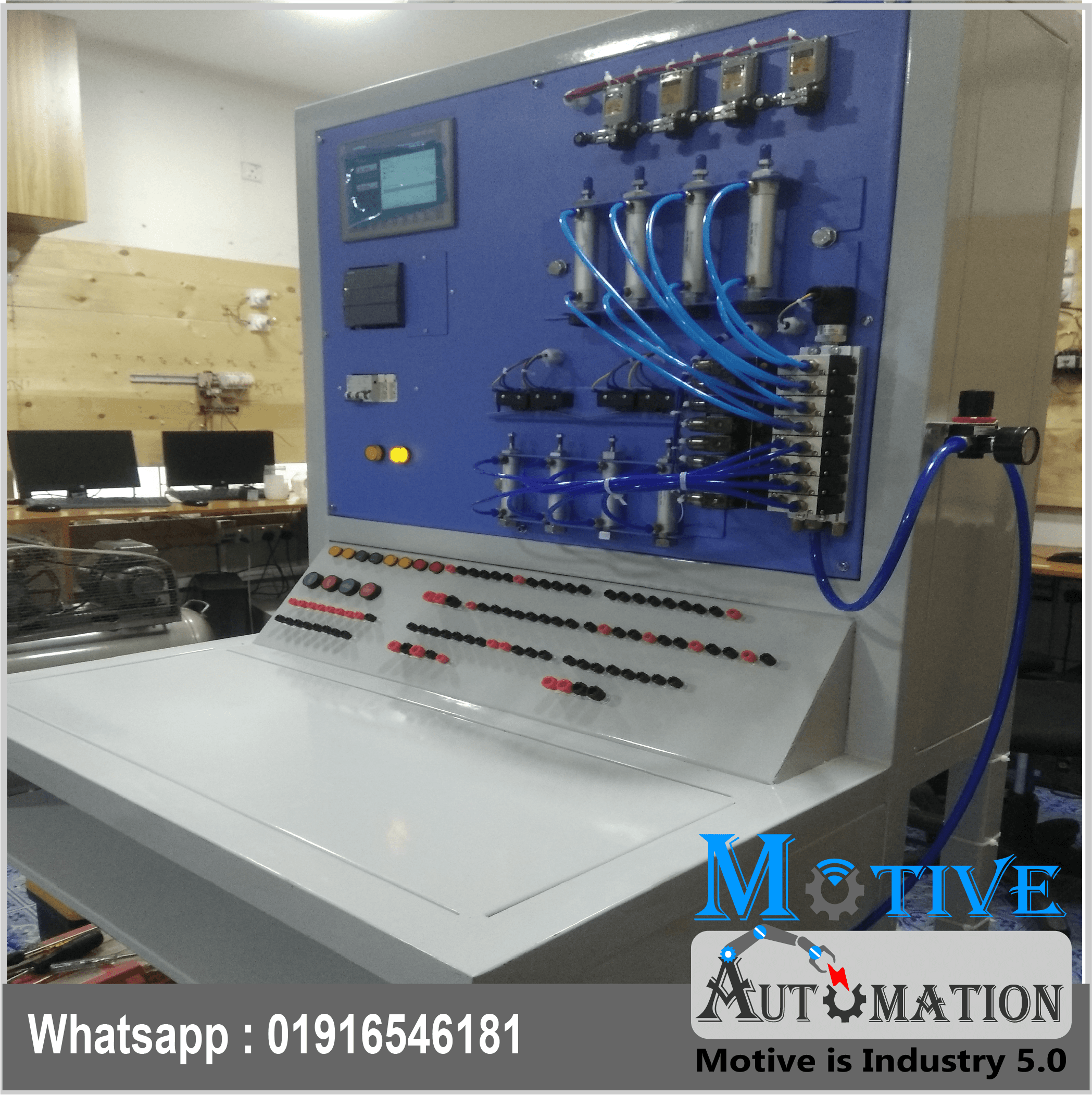

Industrial Pic & Place Robot Trainer

৳ 1,050,000.00

Model: MBD.UISTK002.5

Brand: Motive, BD

🗝️ Key Features: 🤖 3 Axis Robotic Arm

📦 Pick & Place Automation 🖥️ HMI Interface

📐 Predefined Coordinates Programming

📸 Vision Integration (optional) 🔌 I/O Interfacing

🛡️ Safety Emergency System 🧲 Gripper Module

,

Motive BD

,

,

Motive BD

,

🛠️ Industrial Pic & Place Robot Trainer

Model: MBD.UISTK002.5

Brand: Motive, BD

Automated Object Handling with

HMI-Controlled Robotic Arm

This advanced training system

demonstrates industrial automation through a robotic arm programmed to pick

five objects from a conveyor belt and place them at predefined locations.

The entire operation is

managed via a user-friendly Human-Machine Interface (HMI), enabling hands-on

learning in motion control, object detection, and precise robotic positioning.

🗝️ Key Features

🤖 3

Axis Robotic Arm – High-precision industrial-grade robotic arm with

multiple degrees of freedom for flexible movement.

📦 Pick

& Place Automation – Capable of picking five objects from a moving or

static conveyor belt and placing them at designated positions.

🖥️ HMI

Interface – Human-Machine Interface for real-time control, monitoring, and

diagnostics of the robot’s movements.

📐 Predefined

Coordinates Programming – Allows teaching of pick and place coordinates

using HMI or teach pendant.

📸 Vision

Integration (optional) – Machine vision (camera) system can be integrated

for object detection and orientation.

🔌 I/O

Interfacing – Multiple input/output ports to interact with sensors,

actuators, and external devices.

🛡️ Safety

Emergency System – Emergency stop button and protective enclosures to

ensure operational safety.

🧲 Gripper

Module – Vacuum or mechanical gripper to suit various object types

(plastic, metal, etc.).

🎓 Training Features

🧠 Hands-on

PLC & HMI Programming – Trainees learn ladder logic and HMI

configuration for motion control.

🔁 Teach

Programming Concepts – Teach pendant operation, manual and automatic mode

training.

⚙️ Servo

Motor & Drives Understanding – Includes explanation and practical

exercises with servo-based robotic control.

🏗️ Industrial

Integration Skills – Learn how to integrate robot with conveyor, sensors,

actuators, etc.

💡 Debugging

& Troubleshooting Skills – Identify and fix wiring, configuration, and

program-related faults.

🎯 Positioning

Accuracy Calibration – Learn calibration techniques for precise placement.

🧪 Application

Simulation – Simulate real-world tasks such as sorting, packaging, or

inspection.

📊 Parameters & Specifications

|

Parameter |

Value / Description |

|

Number of Axes |

3 DOF |

|

Payload Capacity |

0.2 – .8 Kg (typical for trainer kits) |

|

Repeatability |

±0.5 mm |

|

Conveyor Belt Speed |

Adjustable (0.1 – 1 m/s) |

|

HMI Type |

7″ / 9″ Touchscreen, programmable |

|

Control System |

PLC with HMI |

|

Sensors |

Proximity, Optical, Limit Switch (for positions) |

|

Gripper Type |

Pneumatic |

|

Teaching Method |

Teach Pendant / HMI Programming |

|

Safety |

E-stop, Guard Shields |

3 Degrees of Freedom.

In robotics, Degrees of

Freedom (DOF) refers to the number of independent movements or axes a robot

arm can perform. Each DOF allows the robot to move in a specific

direction or rotation.

✅ In the case of a 3 DOF Robot Arm, it

typically means:

- Base Rotation

– Rotates left and right (Yaw) - Shoulder Movement

– Moves up and down (Pitch) - Elbow Movement

– Also moves up and down (Pitch)

🔧 What it means practically:

- The robot can reach, lift,

and place objects within a 2D/3D space. - It cannot rotate the wrist or

tilt/roll the end effector like more advanced 6 DOF robots. - It’s perfect for basic pick-and-place

tasks, especially in training environments or small-scale automation.

Materials

|

SL No. |

Item Description |

Qty |

Unit |

|

1 |

Panel Type Trainer Steel, |

1 |

Set |

|

2 |

Onboard Spear Parts and Relay 24vdc, 14pin= 6pcs Power Supply 24vdc, 5A=2pcs MCB, MCCB, tower lamp RTC Fuse2A= 2pcs Push Switch=6pcs Toggle Switch=6pcs Proximity Sensor = 5pcs Safety Laboratory Socket = Cable tie and cable lugs Brand: China, Made in China |

1 |

Lot |

|

3 |

SINAMICSV90 servo drive+ Line voltage 200…240V1AC/3AC SINAMICSV90 Pulse train version (PTI) SINAMICSV90 PROFINET version (PN) SIMOTICS S-1FL6 servomotors Brand: SIEMENS Germany |

3 |

Set |

|

|

|

|

|

|

4 |

Main PLC Controller SIEMENS S7 1500 CPU CPU with display; work Brand: SIEMENS Germany |

1 |

pcs |

|

5 |

HMI Touch Display SIEMENS KPT900 Basic PN 6AV2 123-2JB03-0AX0 9” TFT display, 800 x 480 Brand: SIEMENS Germany |

1 |

pcs |

|

6 |

# Robot Arm & Base: Installed Locally As per Sample # Siemens Servo Motor & Drive for Control Robotic Arm # All Kind of fixing Accessories # TIA Portal Software License Version 19 Included 15 days Training facilitation |

1 |

Lot |

|

7 |

DC Power Supply Part No: 6es7505-0ra00-0ab0 System power supply 60W, |

1 |

pcs |

|

8 |

Desktop Computer

Lenovo L22e-30 21.5-inch FHD Monitor / Other

Brand: Lenovo |

1 |

Set |

General Inquiries

There are no inquiries yet.

Related products

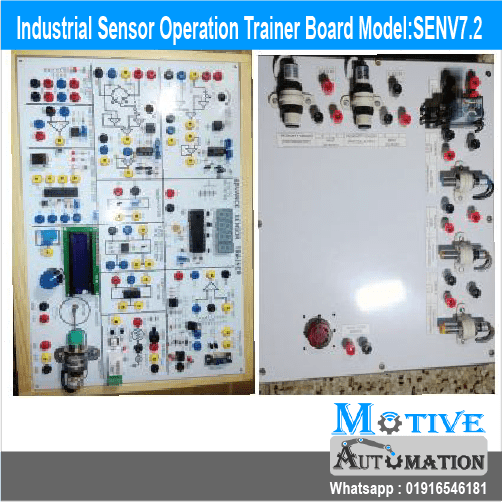

Industrial Sensor Operation Tr...

৳ 120,000.00HMI -KTP400 Basic Color PN- 4&...

৳ 65,000.00S7-1500, CPU 1511-1 PN-6ES7 51...

৳ 180,000.00LS XGB PLC Trainer Board

৳ 85,000.00Analog input module SM 1231 AI...

৳ 28,000.00Advanced PLC Trainer All-in-On...

৳ 950,000.00Microcontroller Trainer Kit

৳ 35,000.00PC Based Digital Oscilloscope

S7-1500 Front connector in pus...

৳ 9,500.00IoT-Based Advanced PLC-SCADA T...

৳ 980,000.003-in-1 Digital Oscilloscope &#...

Electric Trainer Kit Model: DO...

৳ 40,000.00IoT & HMI Based Industria...

৳ 800,000.00HMI -KTP1200 Basic Color PN- 1...

৳ 190,000.00Digital Logic Trainer Kit

৳ 22,000.00Motor Training Equipment, MTE-...

৳ 400,000.00Analog Input/Output Module, SM...

৳ 38,000.00S7-1500,CPU 1511C-1 PN

৳ 250,000.00SIEMENS LOGO PLC Trainer Board...

৳ 65,000.00Industrial Conveyor Trainer Ki...

৳ 450,000.003-IN-1 digital oscilloscope &#...

HMI -KTP1000 Basic Color PN- 1...

৳ 175,000.00S7-1500, DI 32x24VDC HF_1

৳ 54,500.008086 Microprocessor Trainer Ki...

৳ 140,000.00৳ 980,000.00

৳ 950,000.00

Reviews

There are no reviews yet.