Training Kit Power, Automation & Robotics, IoT-EEE

Hotline +8801916546181

Hotline +8801916546181

🛠️ IoT-Based Advanced PLC-SCADA Trainer Board

Model: MBD.S7. APSTB.4ir002.25

Brand: Motive, BD

Service Support: 24 months

The IoT-Based Advanced PLC-SCADA Trainer Board is a state-of-the-art educational platform designed to bridge the gap between industrial automation and Industry 4.0 technologies. It provides practical training in PLC programming, SCADA monitoring, and Industrial Internet of Things (IoT) applications.

🔧 Key Features:

✅ Advanced PLC System – Equipped with industry-standard PLCs (Siemens, Allen-Bradley, or Delta) for real-time automation logic implementation.

✅ SCADA Integration – Includes SCADA software for real-time monitoring, data acquisition, and control of industrial processes.

✅ IoT Connectivity – Enables data transmission via Ethernet, MQTT, or Modbus TCP/IP to cloud platforms or local HMI/SCADA systems.

✅ Sensor & Actuator Interface – Supports integration with various sensors (temperature, pressure, proximity) and actuators (relays, contactors, motors) for simulation of real-world processes.

✅ Remote Monitoring – Access and control the system from anywhere using a secure network interface—mimicking smart factory operations.

✅ Data Logging & Analytics – Collects and stores process data for analysis, improving operational efficiency and predictive maintenance learning.

🎓 Educational Benefits:

- Develops practical skills in PLC programming, SCADA design, and IIoT system integration

- Ideal for students of electrical, electronics, mechatronics, and industrial automation engineering

- Enables understanding of smart manufacturing, real-time process control, and remote diagnostics

Hotline +8801916546181

Hotline +8801916546181

IoT & HMI Based Industrial 3 Phase Motor Control Trainer

Model: MBD. IIoT.MCT002.25

Brand: Motive, BD

Service Support: 24 months

The IoT & HMI-Based Industrial 3-Phase Motor Control Trainer is a cutting-edge educational system designed to teach students and trainees about real-world motor control techniques using modern technologies like HMI interfaces, IoT connectivity, and 3-phase motor control systems. It offers a comprehensive platform for learning industrial automation, remote monitoring, and smart motor operation.

🔧 Key Features:

✅ 3-Phase Induction Motor Control

— Hands-on training with DOL, Star-Delta, and VFD-based control techniques.

✅ HMI Integration

— Real-time monitoring and control through an intuitive HMI interface.

— Display of motor frequency, RPM, and runtime status on the HMI.

✅ IoT Connectivity

— Monitor and control motor operations remotely over the internet via a secure IoT cloud server.

— Supports real-time data logging and status alerts.

✅ PROFINET Communication

— Integrated communication for industry-standard networking and data exchange.

✅ Analog & Digital Signal Handling

— Control motor speed using analog inputs (0-10V / 4-20mA).

— Use digital inputs for logic-based start/stop and direction control.

✅ Alarm & Fault Detection System

— Simulate and monitor industrial faults like phase failure, overload, and overheating with HMI alerts.

✅ Safety & Diagnostics

— Equipped with overload protection, emergency stop, and relay-based safety logic.

🎓 Training Features & Parameters – IoT & HMI-Based Smart Industrial Motor Control

🌐🏭 IIoT & Smart Connectivity

- IIoT – Smart Industrial Connectivity: Learn how to connect and manage industrial devices over the Internet.

- Connected Industrial Devices: Understand real-time interaction between PLC, VFD, HMI, and cloud servers.

- Smart Factory (IIoT Enabled): Build a foundation in Industry 4.0 concepts through live, practical implementations.

Hotline +8801916546181

Hotline +8801916546181

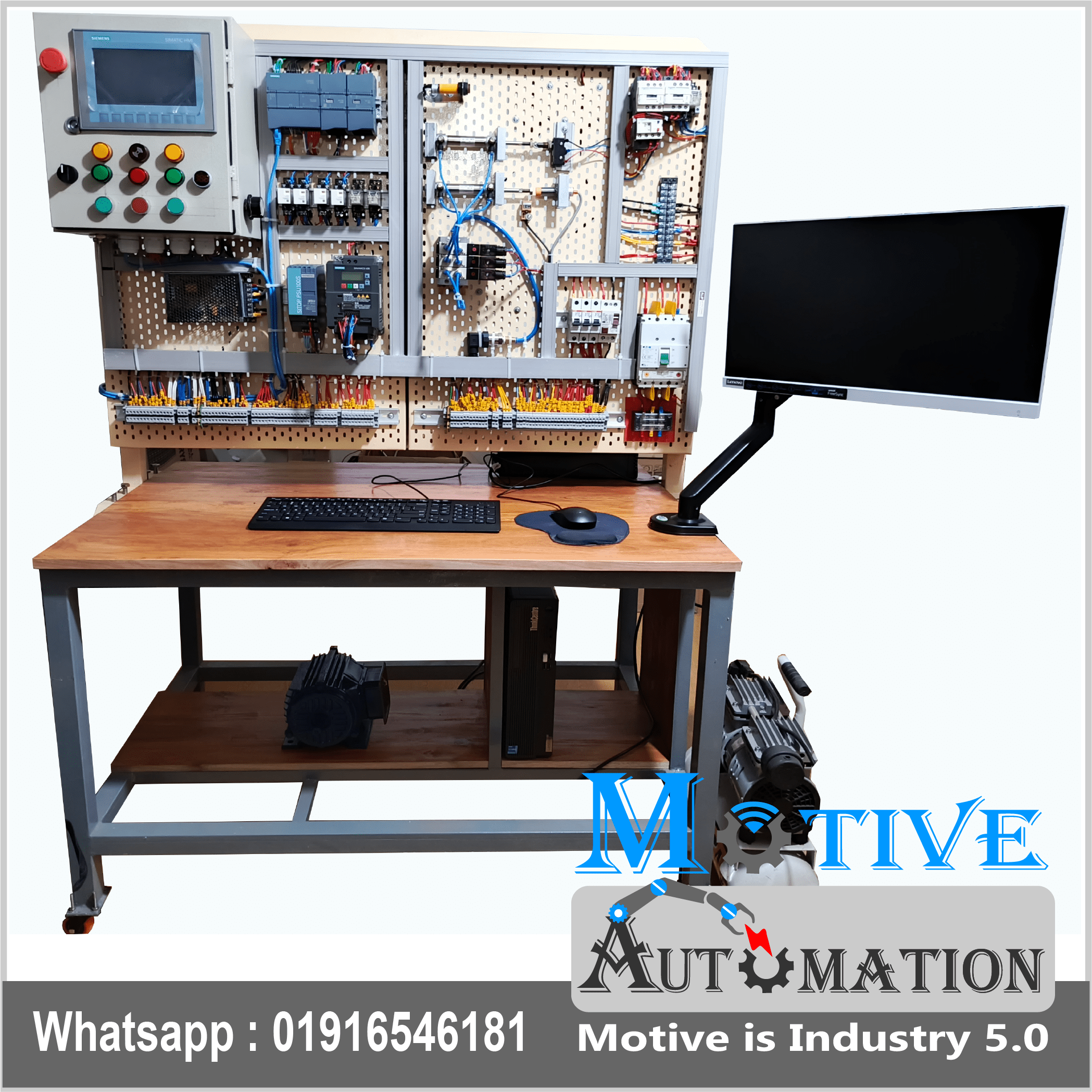

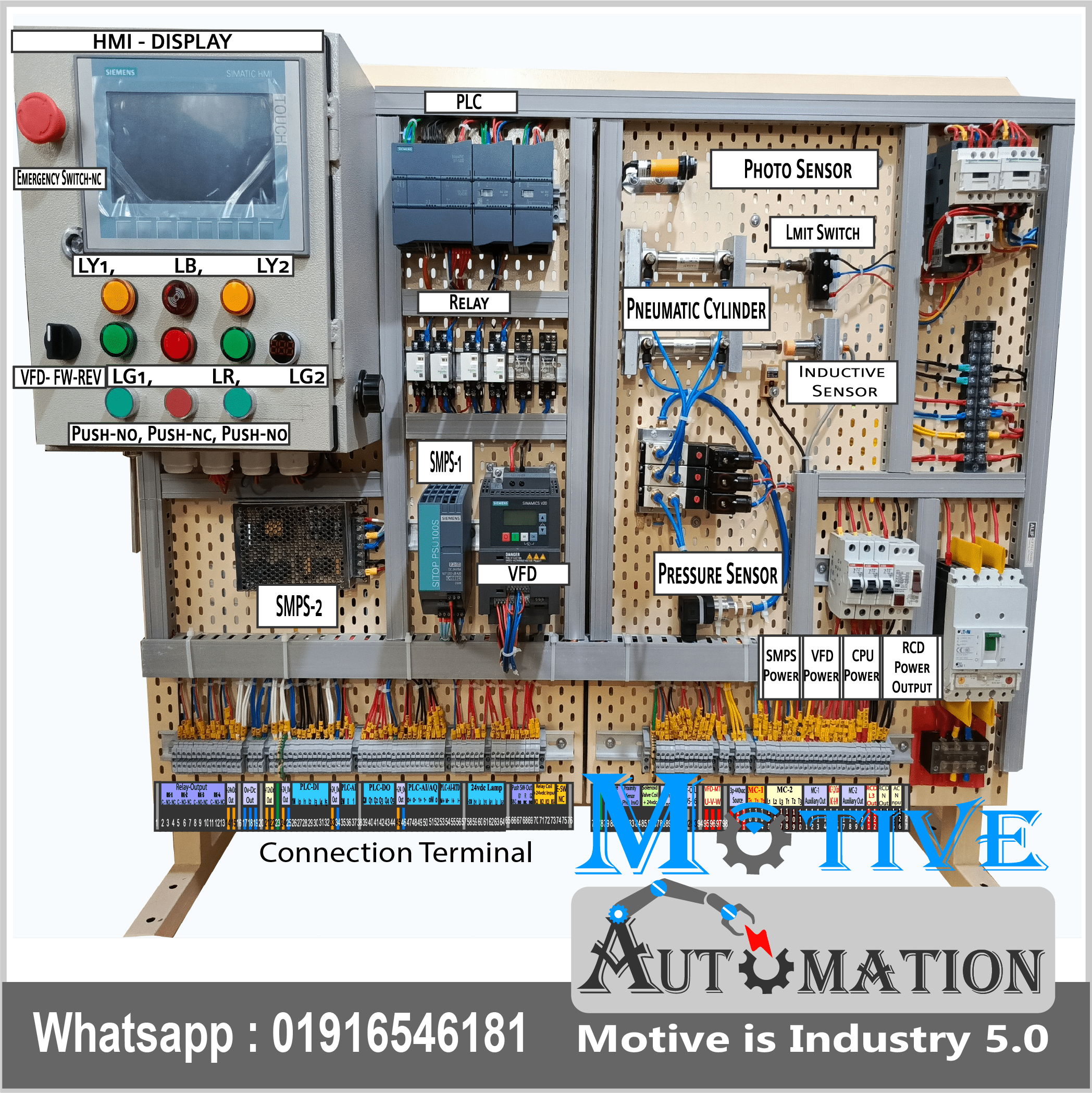

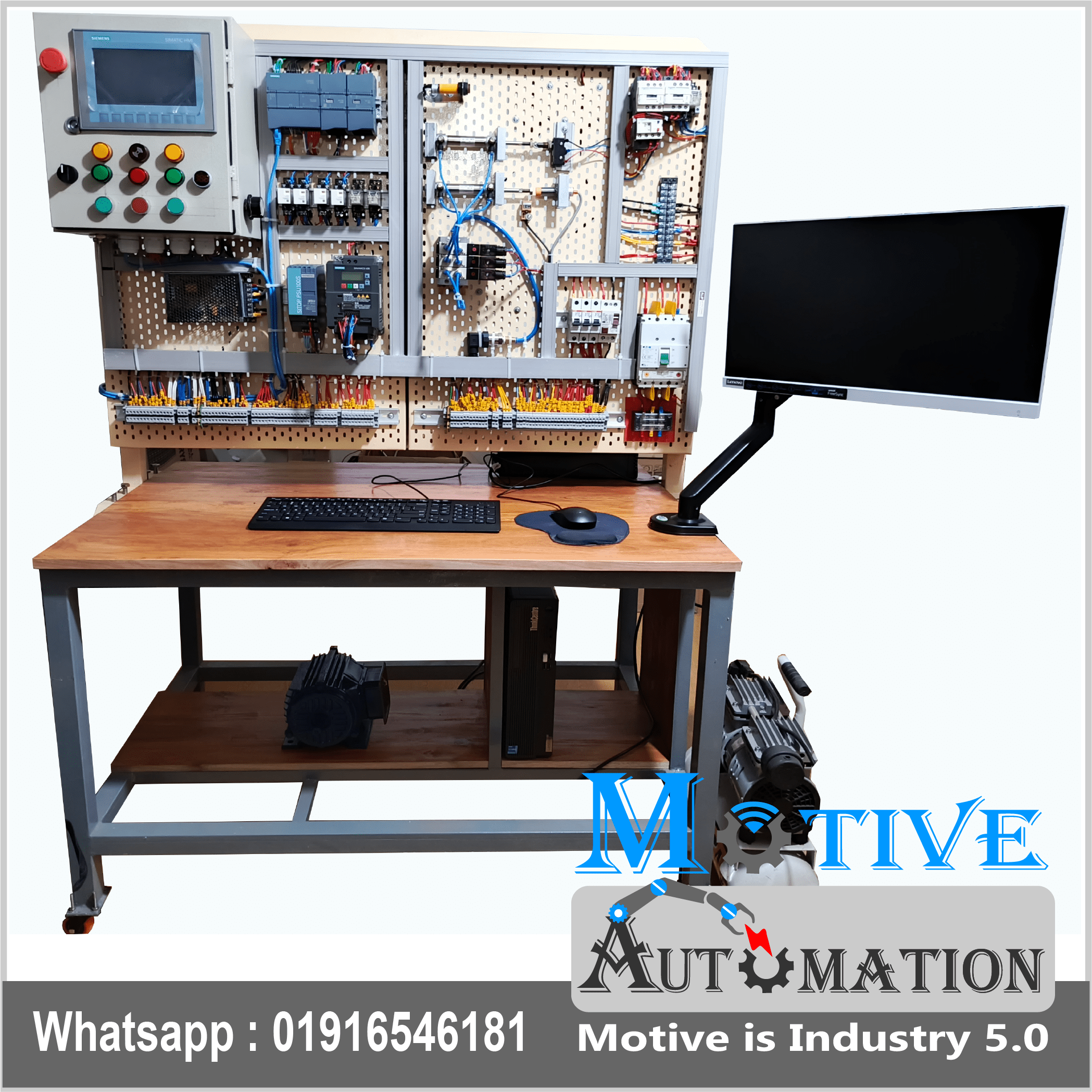

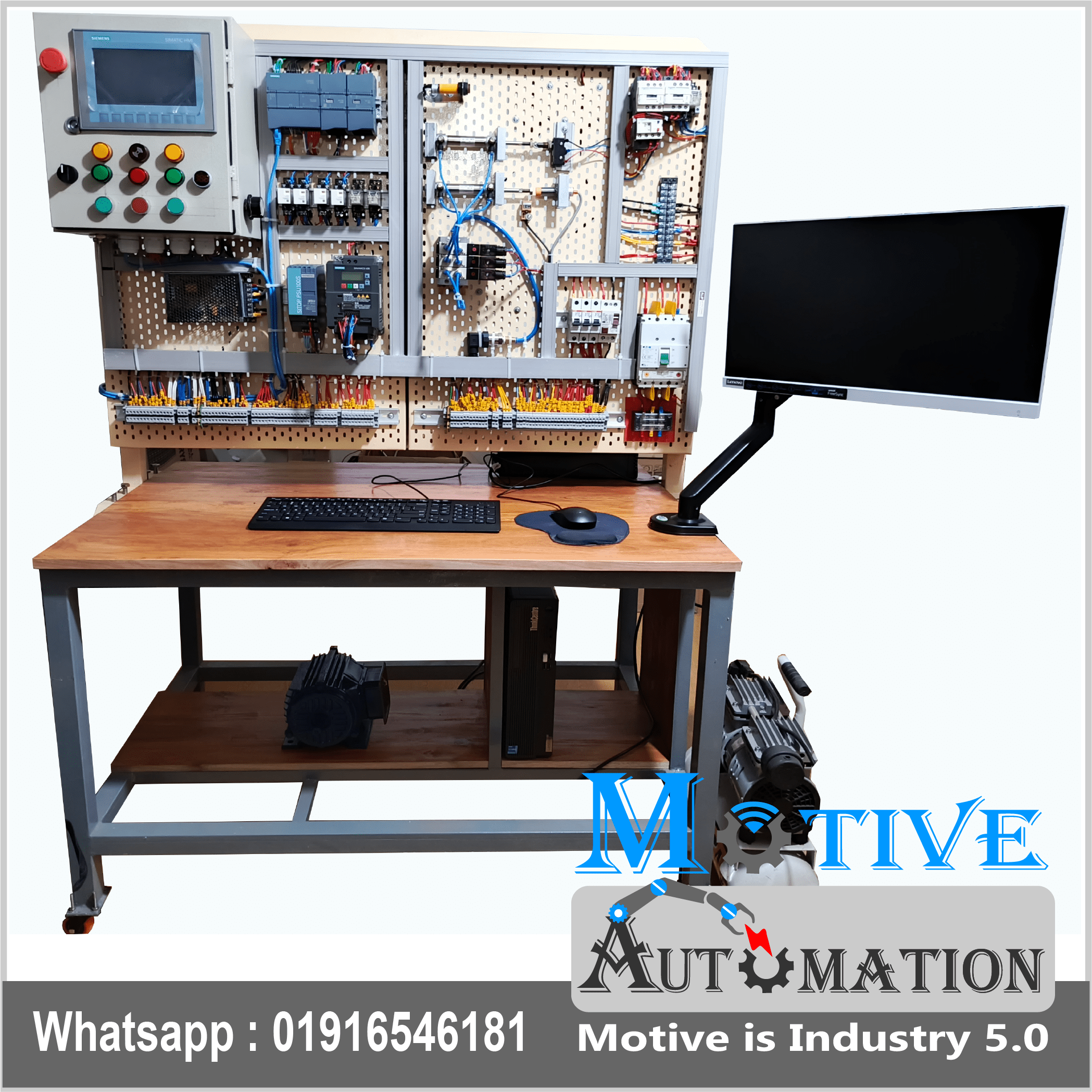

⚙️ SIEMENS Advanced PLC Trainer All-in-One Kit ⚙️

Model: MBD. S7PTA002.25

Brand: Motive, BD

Service Support: 24 months

The SIEMENS Advanced PLC Trainer All-in-One Kit is a compact, modular, and industry-grade training solution designed to deliver hands-on learning in advanced automation and control systems. Built around the powerful SIEMENS S7 series PLCs and featuring HMI integration, this kit is ideal for universities, technical institutes, and industrial training centers aiming to teach real-world PLC programming, smart factory concepts, and industrial automation.

🔧 Key Features:

✅ SIEMENS PLC (S7-1200 / S7-1500)

Learn LAD, FBD, and structured text programming using TIA Portal.

✅ Integrated HMI Touchscreen

Design interactive HMI screens for real-time process control and monitoring.

✅ Digital & Analog I/O Modules

Experiment with sensors, actuators, and analog signals (0–10V / 4–20mA).

✅ VFD Control (Optional)

Interface with a Variable Frequency Drive to control motor speed via analog output.

✅ PROFINET & Modbus Communication

Configure industrial networks and enable seamless communication between PLCs, HMIs, SCADA systems, and third-party devices.

✅ High-Speed Counter Support

Handle encoder inputs and high-speed digital pulses for precision applications.

✅ Industrial Pneumatic Control System

Train on real-world pneumatic components with PLC-based valve control.

✅ Pressure Monitoring & Control

Use sensors to simulate pressure control applications in industrial environments.

✅ Integrated Industrial Bottle Filling Project

Realistic mini-project for automating and monitoring a bottle filling process—ideal for understanding multi-sensor and actuator coordination.

✅ Onboard Sensors & Modules

Includes temperature sensors, proximity sensors, inductive sensors, encoders, relays, and digital indicators.

✅ SCADA Integration (WinCC)

Compatible with SIEMENS WinCC SCADA for real-time data visualization, control, and analytics.

Hotline +8801916546181

Hotline +8801916546181

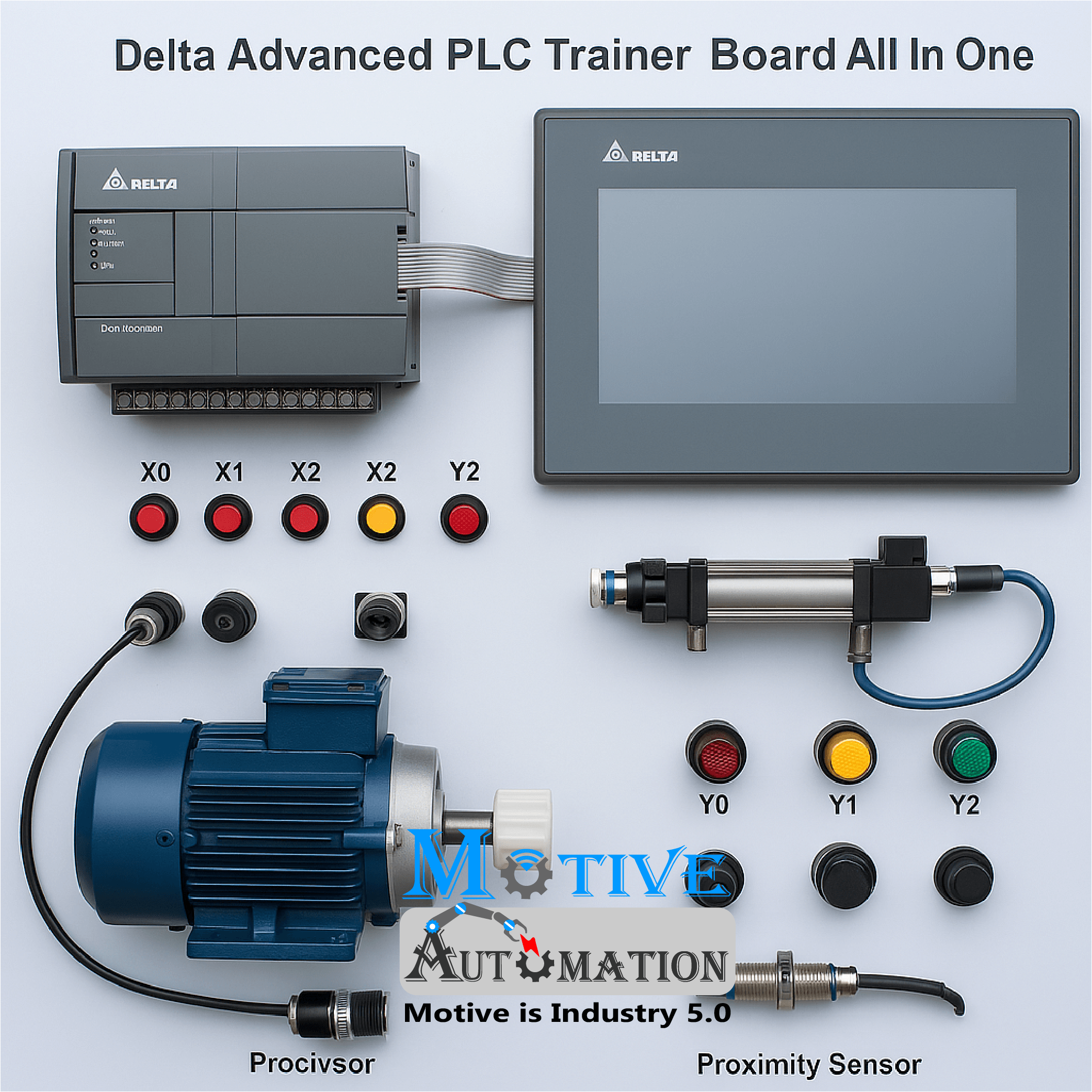

🛠️ Delta Advanced PLC Trainer Board All in One

Model: MBD. DVP.APTB. All002.5

Brand: Motive, BD

Service Support: 24 months

The Delta Advanced PLC Trainer Board All-in-One is a compact, modular, and fully integrated training system built around Delta's industrial-grade PLC and HMI technologies. Designed to meet the needs of modern automation education, this trainer allows students and trainees to explore real-world industrial control systems using Delta's reliable and scalable automation platform.

🔧 Key Features:

✅ Delta PLC (DVP Series)

— Learn ladder logic programming with Delta’s intuitive WPLSoft / ISPSoft platforms.

✅ Integrated HMI (Delta DOP Series)

— Design interactive operator screens for monitoring and controlling devices in real time.

✅ Digital & Analog I/O Modules

— Work with real industrial signals using sensors, switches, analog inputs/outputs (0–10V / 4–20mA).

✅ VFD Control (Delta VFD Included)

— Control 3-phase motor speed through analog signal and monitor feedback via HMI.

✅ Modbus & RS-485 Communication

— Learn industrial communication standards and PLC-HMI networking.

✅ Onboard Sensors & Devices

— Includes temperature sensor, proximity sensor, push switches, indicator lamps, and relay outputs for diverse practical scenarios.

✅ SCADA Compatibility

— Supports SCADA integration for advanced process monitoring and data logging.

✅ IoT Ready

— Optional cloud connection for remote monitoring and control of industrial processes.

✅ Safety Features

— Emergency stop switch, overload protection, and clearly labeled terminals for safe learning.

Hotline +8801916546181

Hotline +8801916546181

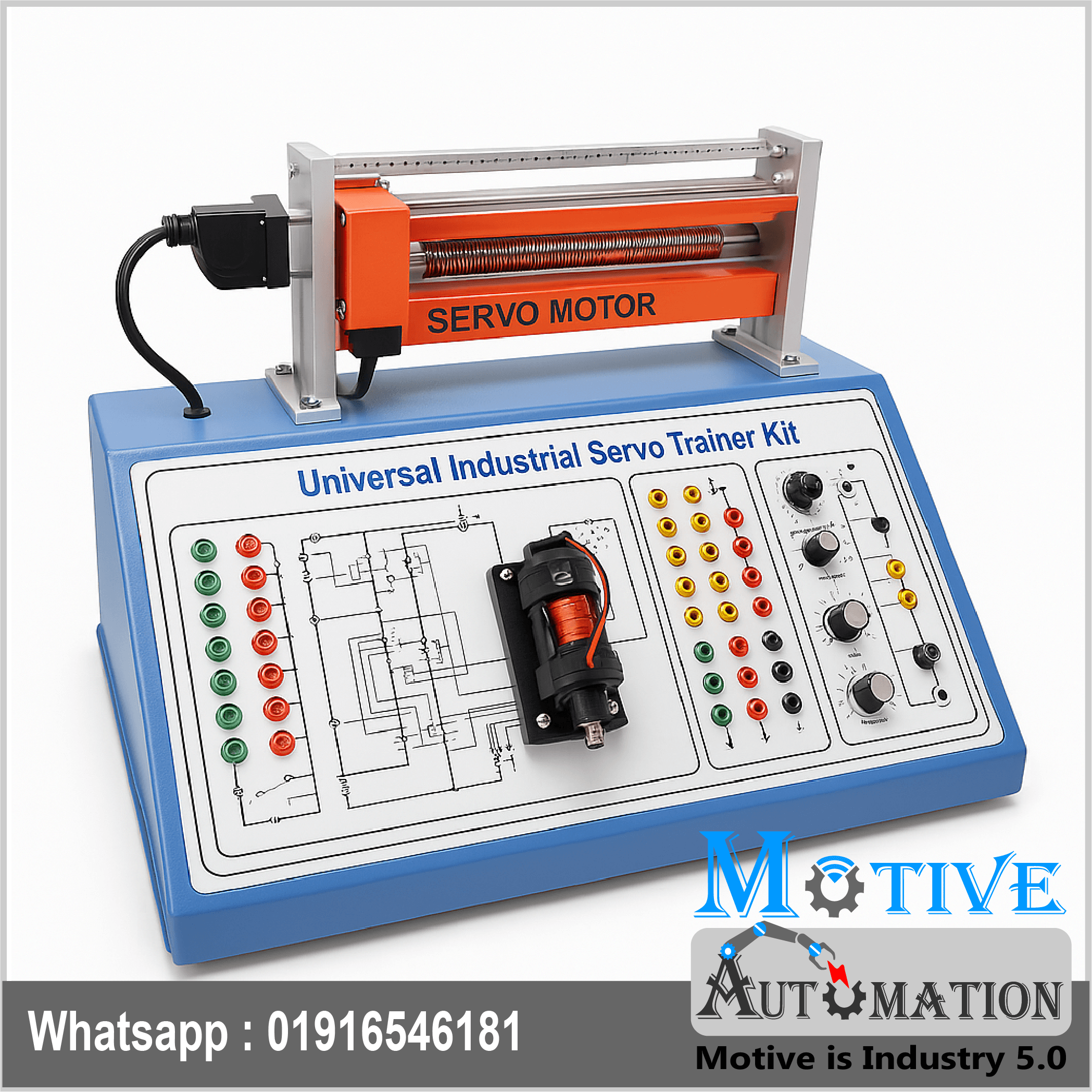

🛠️ Universal Industrial Servo Trainer Kit

Model: MBD.UISTK002.5

Brand: Motive, BD

Service Support: 24 months

A versatile and modular trainer system designed for practical hands-on learning and industrial automation training with AC, DC, and servo motors. Ideal for control system training, robotics education, and motion control diagnostics.

🔧 Key Features

🔌 Multi-Servo Compatibility

Supports AC Servo Motors, DC Servo Motors, Stepper Motors

Interfacing with major brands (LicOS, Mitsubishi, Delta, emtech, Panasonic JSS, etc.)

🧠 Industrial Controller Integration

PLC-Interface (Siemens, Delta, Mitsubishi etc.)

HMI panel for real-time parameter display

SCADA/PC interface via RS-232/RS-485 or Ethernet

🖥️ Graphical Monitoring

Real-time feedback on position, torque, speed, and current

Optional PC software for waveform visualization

⚙️ Real Hardware Interfacing

Encoder feedback support

Brake control simulation

Load simulation (using dynamic brakes or pulley system)

📦 Modular Design

Plug-in modules for different servo drives and motors

Open wiring panel for practicing wiring connections

📲 Control Modes

Position Control

Speed Control

Torque Control

Jog and Auto Mode Selection

🔒 Safety Features

Emergency stop button

Short circuit and overload protection

Isolated signal and power sections

📊 Digital Display

RPM, Position (Encoder count), Voltage/Current monitoring

Hotline +8801916546181

Hotline +8801916546181

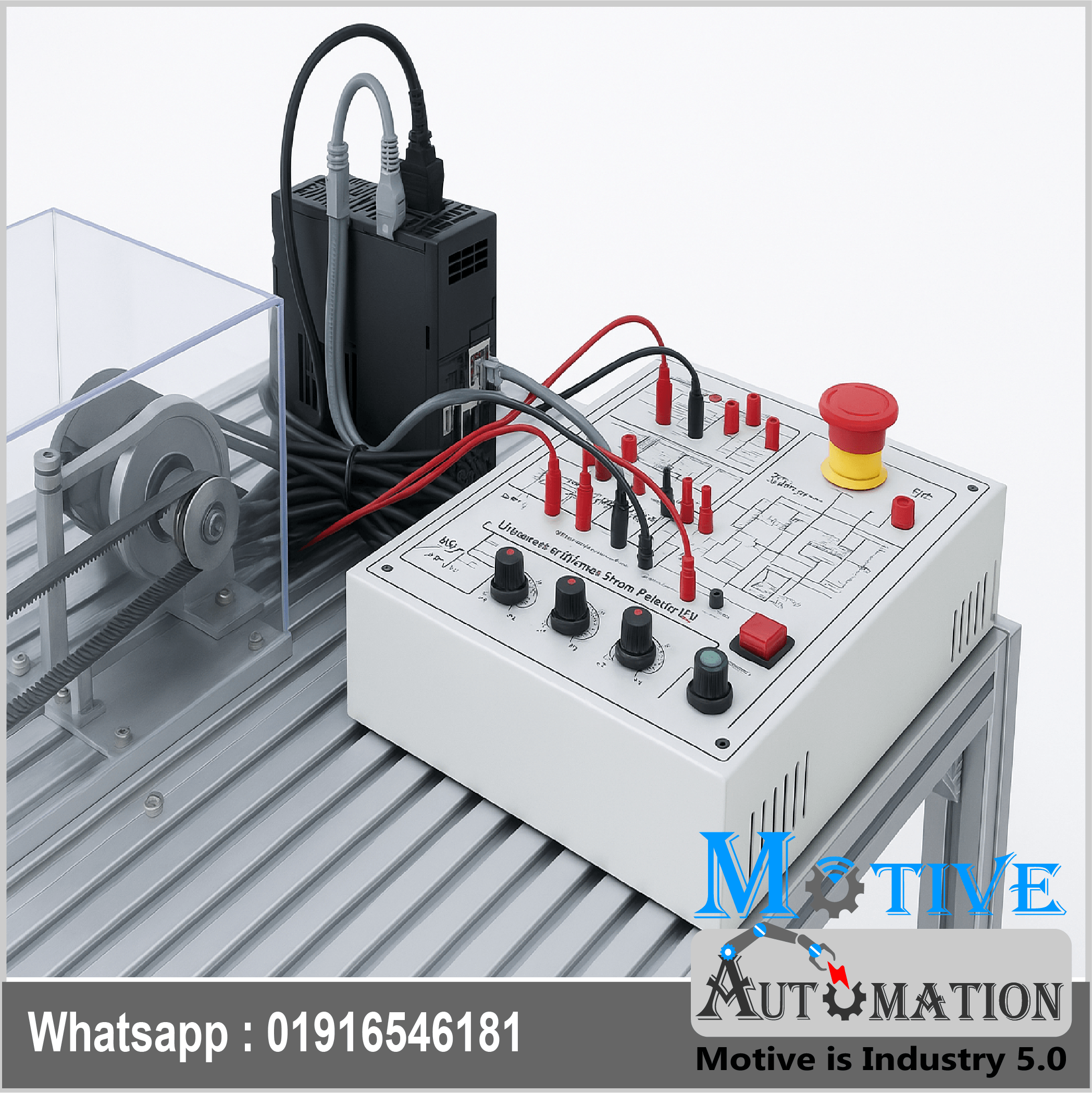

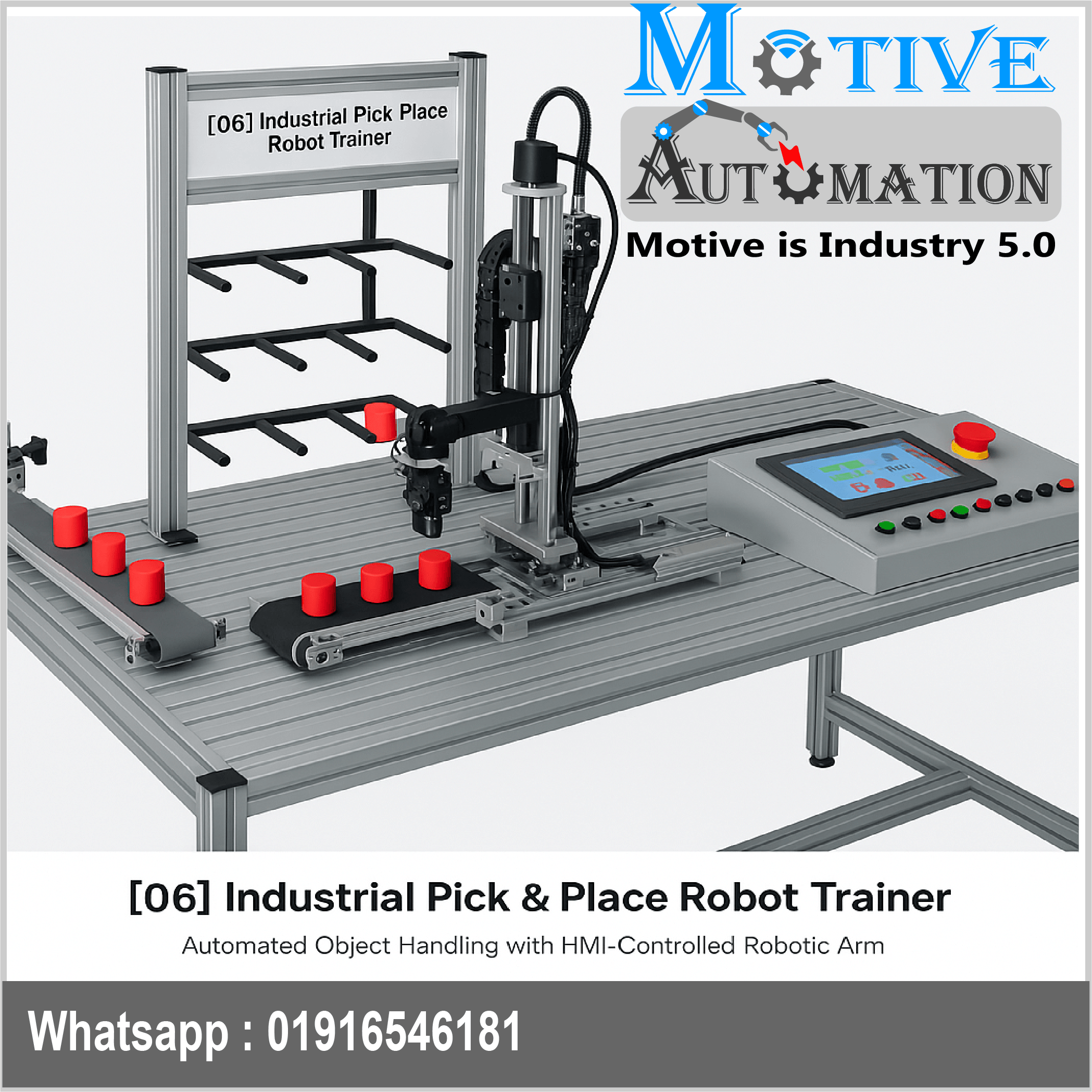

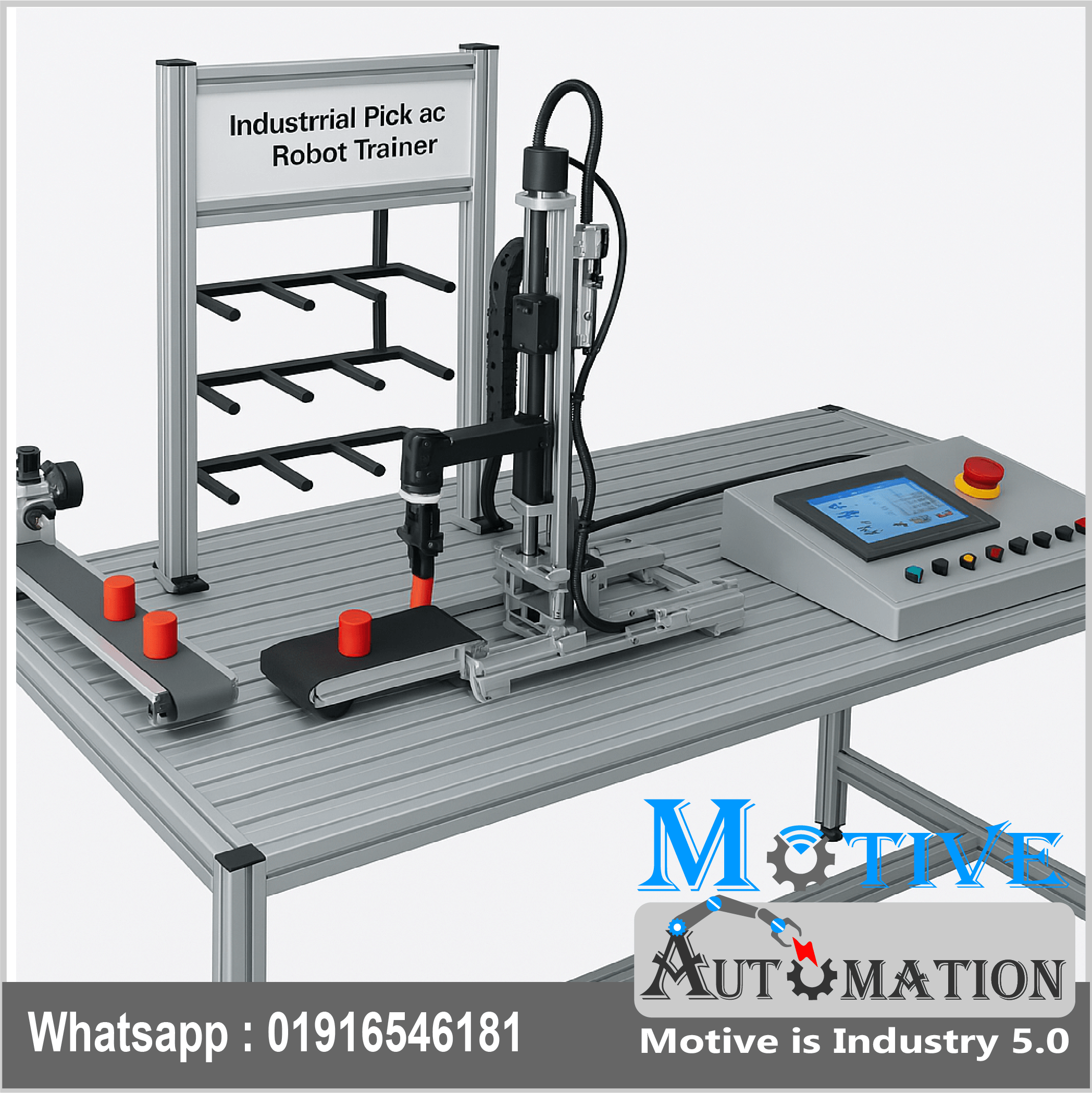

🛠️ Industrial Pic & Place Robot Trainer

Model: MBD.UISTK002.5

Brand: Motive, BD

Service Support: 24 months

Automated Object Handling with HMI-Controlled Robotic Arm

This advanced training system demonstrates industrial automation through a robotic arm programmed to pick five objects from a conveyor belt and place them at predefined locations.

The entire operation is managed via a user-friendly Human-Machine Interface (HMI), enabling hands-on learning in motion control, object detection, and precise robotic positioning.

🗝️ Key Features

- 🤖 3 Axis Robotic Arm – High-precision industrial-grade robotic arm with multiple degrees of freedom for flexible movement.

- 📦 Pick & Place Automation – Capable of picking five objects from a moving or static conveyor belt and placing them at designated positions.

- 🖥️ HMI Interface – Human-Machine Interface for real-time control, monitoring, and diagnostics of the robot’s movements.

- 📐 Predefined Coordinates Programming – Allows teaching of pick and place coordinates using HMI or teach pendant.

- 📸 Vision Integration (optional) – Machine vision (camera) system can be integrated for object detection and orientation.

- 🔌 I/O Interfacing – Multiple input/output ports to interact with sensors, actuators, and external devices.

- 🛡️ Safety Emergency System – Emergency stop button and protective enclosures to ensure operational safety.

- 🧲 Gripper Module – Vacuum or mechanical gripper to suit various object types (plastic, metal, etc.).

Hotline +8801916546181

Hotline +8801916546181

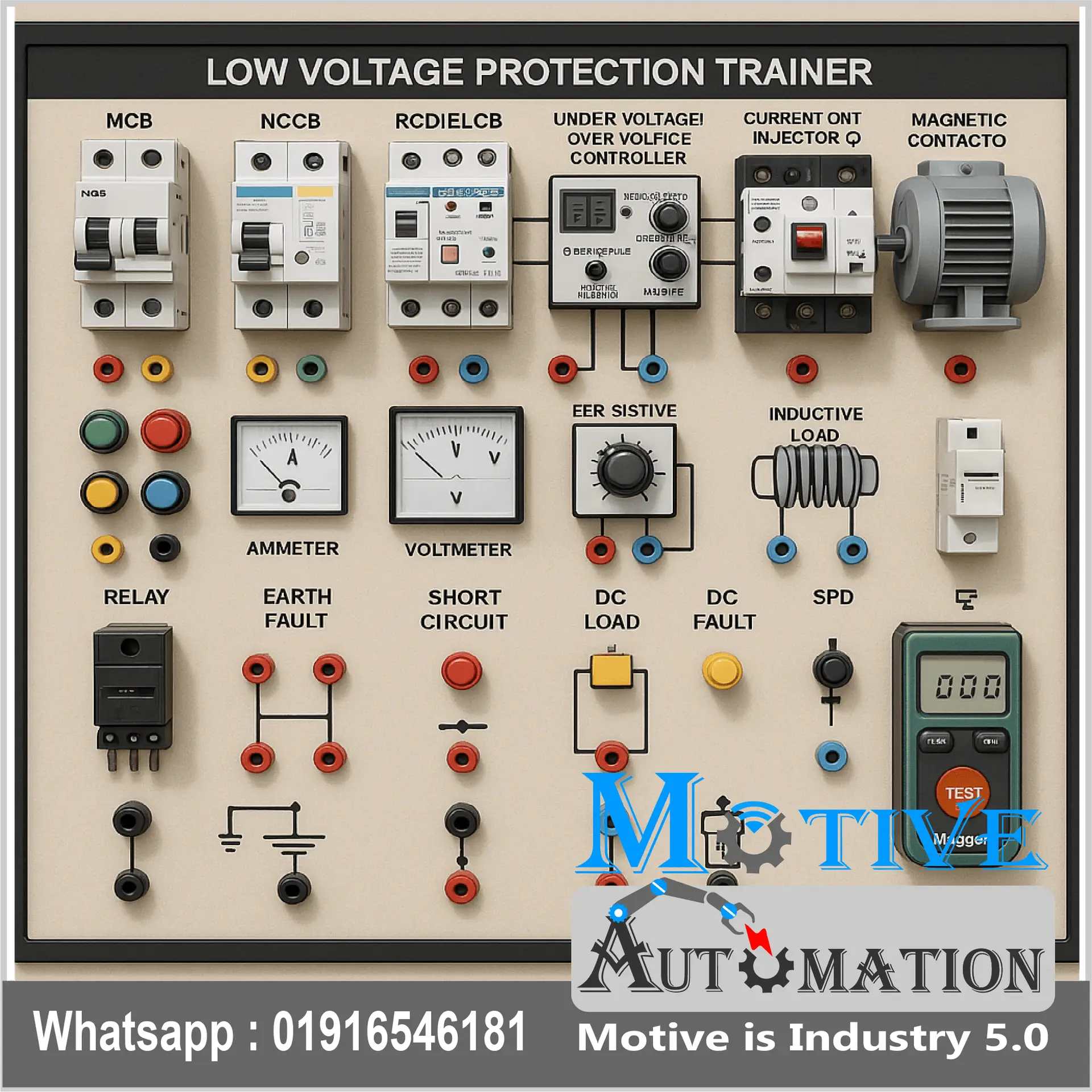

🛠️ Low Voltage Protection Trainer – Advanced Educational Model

Model: MBD.LVPT002.5

Brand: Motive, BD

Service Support: 24 months

The Low Voltage Protection Trainer is a versatile, hands-on educational tool designed to teach the principles, functions, and real-world applications of low voltage protection systems. It offers a safe and modular environment to explore undervoltage, overcurrent, and earth fault protection scenarios using industry-standard components.

Ideal for vocational institutes, engineering labs, and technical training centers, this trainer allows learners to test, wire, and evaluate devices like MCBs, MCCBs, RCBs, RCBOs, and protection relays.

🌟 Key Features

- Modular Layout: Clearly labeled components mounted on acrylic or transparent panels.

- Real-World Fault Simulation: Simulate undervoltage, short circuit, and earth fault scenarios.

- Built-in Protection: Integrated overcurrent, undervoltage, and earth fault mechanisms.

- Digital Instrumentation: On-board CT-based ammeter and digital voltmeter.

- Visual Indicators: LED lamps to indicate ON/OFF and fault status.

- Emergency Stop: Instant shutdown during fault or hazard.

🎓 Training Features

✅ Understanding of Low Voltage Protection Circuits

✅ AC/DC Protection Relay Integration

✅ Repairable On-board Low Voltage Fuses

✅ Complete Circuit Breaker Setup:

- MCB (Miniature Circuit Breaker)

- MCCB (Molded Case Circuit Breaker)

- RCB (Residual Current Breaker)

- RCBO (Residual Current with Overcurrent)

✅ MCB Characteristics Testing (B, C, D Curve behavior)

✅ Short Circuit & Earth Fault Testing for all CBs

✅ Adjustable AC Variable Power Supply

✅ Current Injector for overcurrent simulation

✅ AC Motor Protection Circuit using magnetic contactor and thermal OLR

✅ Manual & Automatic Restart Testing

✅ Resistive & Inductive Loads for load-based circuit behavior

✅ Manual Fault Simulation Switches

✅ Practical Wiring & Troubleshooting Exercises

Hotline +8801916546181

Motor Training Equipment, MTE-003.1DC

Overview: The training device includes various types of motors and industrial control components. Through relevant experiments, you can familiarize yourself with the operating characteristics of DC motors and the use of various industrial control components, master the control principles and control methods, and cultivate students’ corresponding knowledge and Skills, suitable for higher vocational, higher vocational, secondary vocational schools and technical and vocational schools related teaching and skills training assessment

Hotline +8801916546181

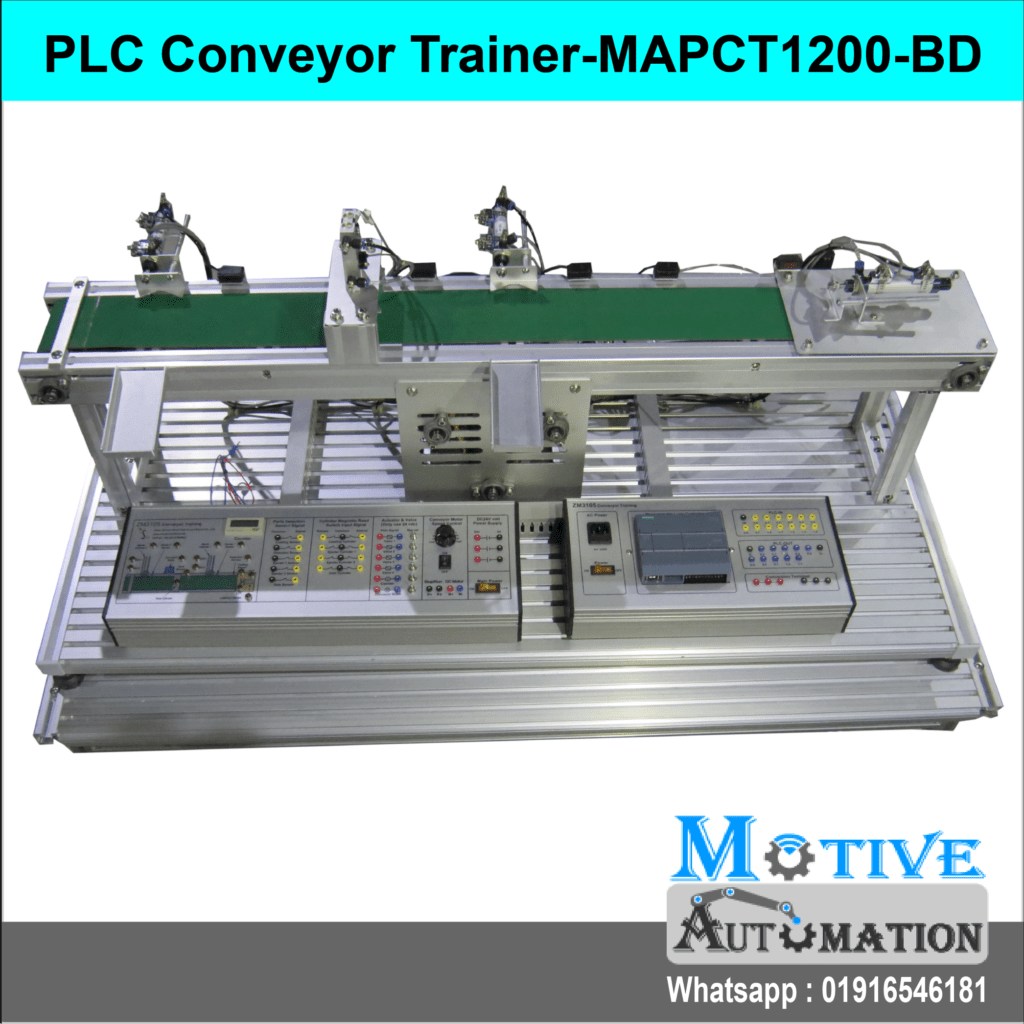

PLC Conveyor Trainer-MAPCT1200-BD

Overview

Conveyor control system is a training system which can meet practical field , it can sufficient simulate industrial field automatic production line. This system combined with realistic conveyor system production line, it can make the student improve the understanding of automatic conveyor production system. System mainly be made up of air cylinder, solenoid valve, sensor, motor and programmable logic controller, etc. It is based on a draper-type conveyor, install sensor on different positions for checking the convey objective on the belt. According to input the signal of sensor to programmable logic controller, make the PLC output signal control solenoid valve and cylinder according to requirement, it can realize the sort and count for objective on belt.

This training equipment is consisted of various kinds industrial sensor, pneumatic control unit, electrical switch, PLC programmable logic controller, etc. It make up a mechanotronics mechanical-electrical integration equipment mechanical platform which including loading unit, convey unit, detection module, classified storage and other working area. According to related experiment, student can understand the pneumatic system actuator operation characteristic, understand the connection method of industrial sensor and PLC, master the

PLC programming technique, etc, it can cultivate student corresponding knowledge and technical ability, it can suitable the teaching and technical ability training examine of related specialties of higher vocational college, college and secondary vocational schools, etc.

Industrial Conveyor Trainer Kit - MAICT-WP24-BD

Technical Specification:

Model:CBV7.2

Technical Specification:

(Mechanical Size:18”x12”x6”/16”x10”x6”)

Training feathers and Parameter:

1.PLC Operated Instrument

2.Supply Voltage-42Vdc

3.Mini Servo Motor (24vdc)

4.Servo operation plc card

5.Servo PWM Speed Controller

6.Product counting proximity sensor

7.9999 Counter display

8.Product Sorting Motor

9.Error detecting signal buzzer

10.Error detecting signal lamp

ETC.

Hotline +8801916546181

Universal PLC Trainer Board, APSL0BA6/8

Technical Specification:

Model No: APSL0BA6/8

Main CPU Siemens Logo-0BA8 (Board Mechanical Size:20”x18”x6”/16”x14”x6”)

Supply Voltage: 220VAC/24VDC

Training feathers and Parameter:

1. Logic gate operation (AND, OR, NOT, NOR,NAND,EX-OR,EX-NOR)

2. LED Digital Control

3. Traffic Light Control

4. Water level Control

5. Servo Motor – Optional

6. Proximity Sensor Control

7. 3 Phase Motor Control

8. Optical Sensor Control

9. Security Alert System

10. 8 digital input,4 Analog input (4-20ma,0-10vdc), 4 digital output

11. 10 On board Application Using PLC & Analog Function

12. Servo motor Driver- Optional

13. 8 SPST and 4 Push button Switch

14. Communication Port

15. Relay and Transistor Output-24VDC

User friendly windows based software

Hotline +8801916546181

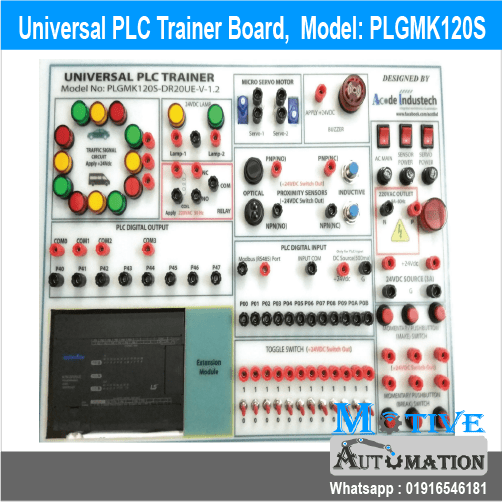

Universal PLC Trainer Board

Feathers:

Model: PLGMK120S

Main CPU

LS Master-K-120S-K7m (Board Mechanical Size:20”x18”x6”/16”x14”x6”)

Supply Voltage: 220VAC/24VDC

Training feathers and Parameter:

1.Logic gate operation (AND, OR, NOT, NOR, NAND, EX-OR, EX-NOR)

2.LED Digital Control

3.Traffic Light Control

4.Water level Control

5.Servo Motor -Optional

6.Proximity Sensor Control

7. 3 Phase Motor Control

8.Optical Sensor Control

9.Security Alert System

10. 12 digital input, 8digital output

11. 10 On board Application Using PLC & Analog Function

12.Servo motor Driver- Optional

13. 12 SPST and 6 Push button Switch

14.Communication Port

15.Relay and Transistor Output-24VDC

User friendly windows based software

Hotline +8801916546181

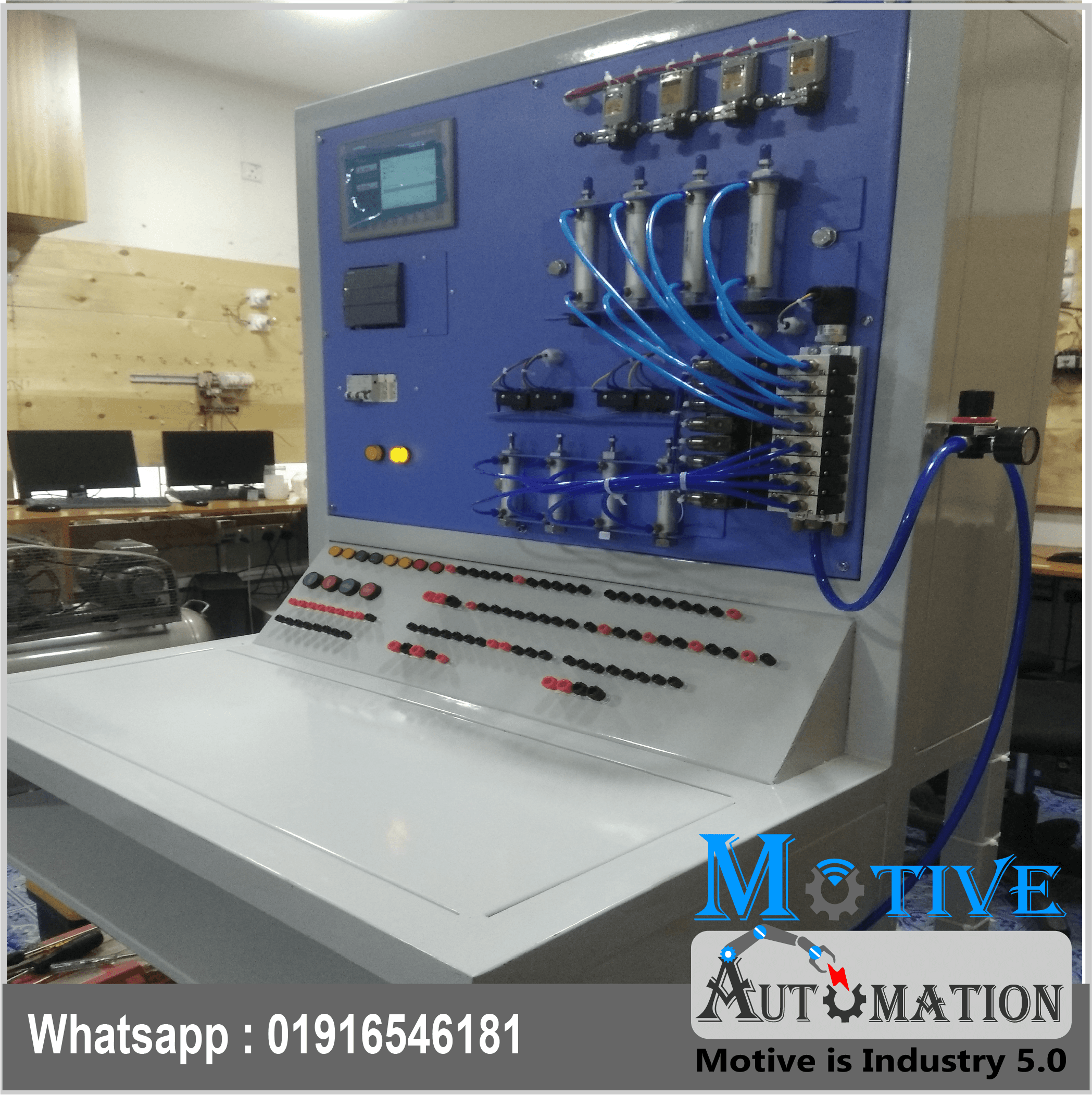

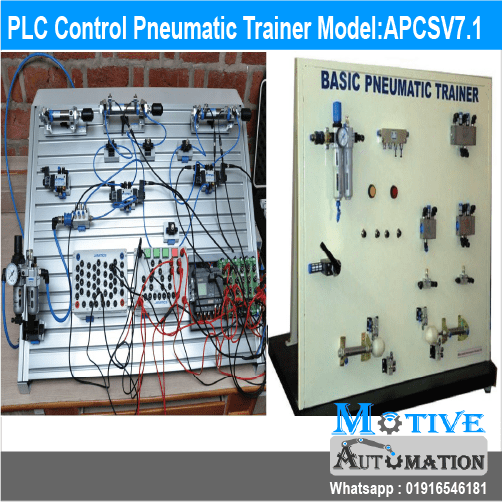

PLC Control Pneumatic Trainer Model: APCSV7.1

Technical Specification:

Mechanical Size (16”x14”x6”)

Supply Voltage: 220VAC/24VDC

Training feathers and Parameter:

This trainer Very useful to study the Basic Level Electro

Pneumatics Kit with PLC Components like FRL,

Solenoid valve, cylinder, One Reputed Make PLC etc

Student scan makes Design and verifies the circuit

pneumatic level operation using this kit.

Overview: The training device includes various types of motors and industrial control components. Through relevant experiments, you can familiarize yourself with the operating characteristics of DC motors and the use of various industrial control components, master the control principles and control methods, and cultivate students’ corresponding knowledge and Skills, suitable for higher vocational, higher vocational, secondary vocational schools and technical and vocational schools related teaching and skills training assessment

Hotline +8801916546181

Electric Trainer Kit Model: DOL-FR-SD-V1.2

Technical Specification:

(AC Motor Driver-Delta/Mitsubishi/LS-.75KW)

Operating Voltage 220VAC/415V AC 3 Phase

Training feathers and Parameter:

1) Three Phase Induction Motor Control.

2) Star-Delta Operation

3) DOL Starter

4) Forward – Reverse Operation

5) Series – Parallel Operation

6) Onboard Thermal Overload Relay, Ampere Meter, Voltmeter

Hotline +8801916546181

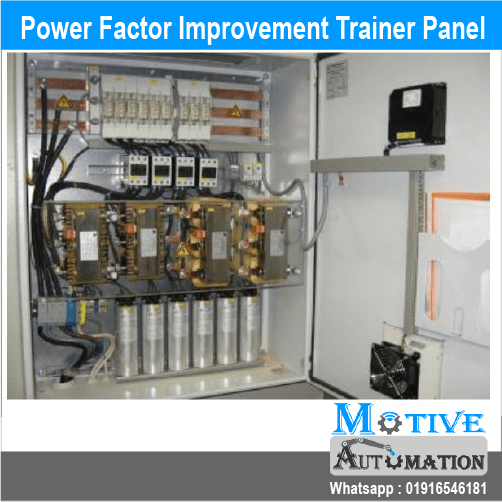

Power Factor Improvement Trainer Panel, Model:PFI60KVAR

Technical Specification:

(Mechanical Size :4’x2’x8”) Metal body

Operating Voltage 220VAC/415V AC 3 Phase

Automatic Power Factor Control Panels are mainly used for the improvement

of Power Factor. Power Factor can be explained as ratio of active power to

apparent power and it is a key factor in measuring electrical consumption.

Everyone knows that how costly electricity has become in present time.

In this trainer Student can lag/lead the power factor and can Observe the

Inductive & Capacitive load condition.

Training feathers and Parameter:

1) Manual Power Factor Improvement using capacitor bank

2)Automatic Power Factor Improvement using Micro Relay

3) On board Inductive load

4) On board capacitive load

5)Busbar system with HRC Fuse

6)PFI Meter Analog and Digital

7) Onboard Ammeter and Voltmeter

8)Supplied with connecting cables and User Manual

Hotline +8801916546181

Basic Electrical Low Voltage Protection Trainer Model:LVPTV1.2

Technical Specification:

Operating Voltage: 415VAC/ 220VAC/24VDC

Mechanical Size (12”X10”X6”) Metal &Wooden body

Training feathers and Parameter:

1) Included Protection Relay (AC-DC)

2) Included on board Low voltage fuse (Reparable)

3) Included Circuit breaker (MCCB, MCB,RCB, RCBO)

4) MCB Characteristics Test

5) MCB, MCCB,RCB,RCBO Short Circuit and Earth Fault test

6) On boar AC Variable power supply

7) On boar Current Injector

8) AC Motor Protection Circuit with Magnetic Contact

9) On Board Digital Ammeter CT type and Digital Voltmeter

10) Included Resistive and Inductive load

Leave a reply